On Dec. 9 (Beijing time), the group of Prof. Yiping Guo from the State Key Laboratory of Metal Matrix Composites of Shanghai Jiao Tong University, School of Materials Science and Engineering, together with the Shanghai Institute of Silicate, Chinese Academy of Sciences, and the University of Wollongong, Australia, made a major breakthrough in the field of lead-free piezoceramic materials, the related results were published in Science under the title "Giant electric-field-induced strain in lead-free piezoceramics". The study found that by introducing defective dipoles and modulating the phase structure and ferroelectric domain structure, a giant strain (1.05%) and a large-signal piezoelectric strain coefficient (d33*~2100 pm/V) were achieved in Sr2+-doped (K,Na)NbO3 (KNN) lead-free piezoceramics, while the research strategy endowed the piezoceramics with a low driving electric field, superior temperature stability and fatigue resistance, and low hysteresis. It paves the way for replacing commercial PZT lead-based ceramics with promising applications in microelectromechanical systems (MEMS), ultra-precision processing, integrated circuit manufacturing, precision optical instruments, bioengineering, and medical science. Prof. Yiping Guo is the corresponding author of this paper, PhD student Geng Huangfu is the first co-author, and Shanghai Jiao Tong University is the first unit. The main collaborators of the research work include the research groups of Researcher Fangfang Xu and associate researcher Zhengqian Fu, at the Shanghai Institute of Silicate, Chinese Academy of Sciences, and Professor Shujun Zhang's group at the University of Wollongong, Australia.

Research of Prof. Yiping Guo's group published online in Science

The current commercial piezoelectric actuators are mainly composed of lead zirconate titanate (PZT) ceramics with lead oxide content over 60 wt%, which can bring harm to the ecological environment and sustainable development of human society in the process of preparation, use, recycling and disposal. in August 2017, the EU RoHS Directive Recommendation Committee publicly released information indicating that some lead-based piezoelectric products will no longer be exempted from the EU market in 2021. The Materials Research Society (MRS), a global materials research benchmark, established a lead-free piezoelectric materials session for the first time in 2020. The development of environmentally friendly lead-free ferroelectric materials has become an important scientific frontier and technical competition focus in the field of functional materials internationally. The vigorous development of environmentally friendly and green lead-free piezoelectric materials and devices is in line with the basic national policy of "green water and green mountains are the silver mountain of gold" in China.

Since the innovative preparation of positive piezoelectric coefficient KNN-based ceramics (d33~245 pC/N) with high voltage electrical activity by Prof. Yiping Guo in 2004, KNN-based lead-free piezoceramics have made remarkable progress in the research of small signal d33, and their d33 values have reached the level of PZT. However, they also suffer from the problems of complex composition, poor repeatability and temperature stability. In the development of large-signal d33* piezoelectric ceramics for driver applications, materials comparable to lead-based PZT ceramics have never been found (high inverse piezoelectric coefficient at low driving electric fields, superior temperature stability and fatigue resistance, low hysteresis, etc.). Therefore, the development of lead-free piezoelectric ceramics with simple composition and process and aiming at practical applications is an urgent challenge to be tackled.

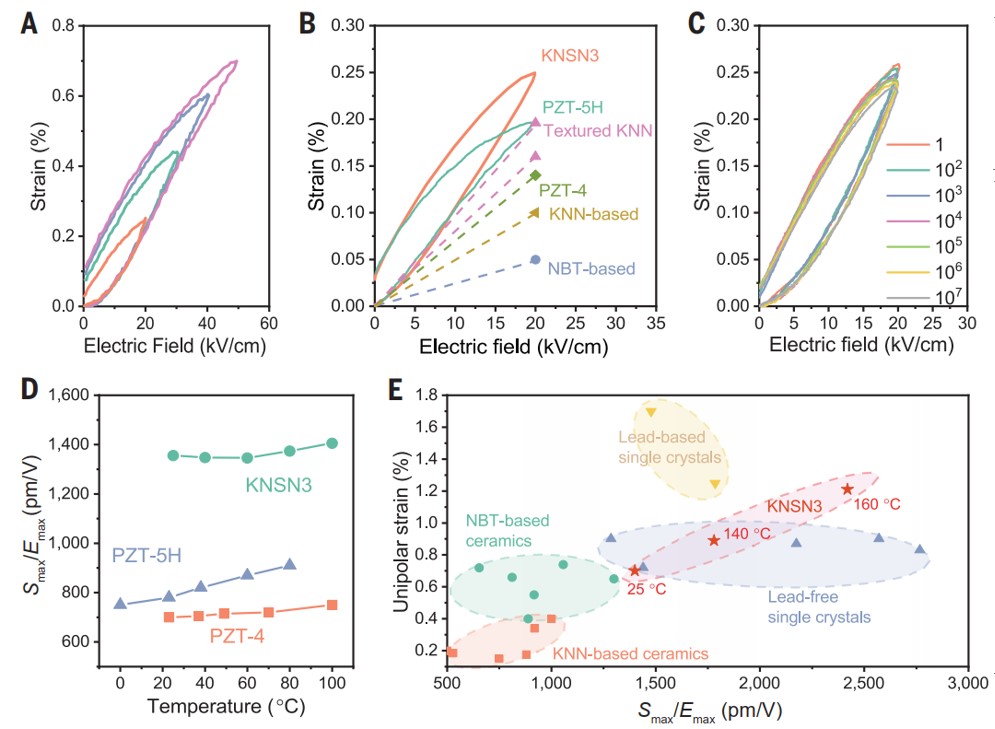

In this study, the introduction of Sr2+ into KNN is like a drop of manna in the desert, which not only solved the problem of difficult sintering of KNN ceramics, but also regulated the K+/Na+ vacancy and oxygen vacancy content as well as the phase structure and ferroelectric domain structure of the ceramics, which can be considered as a multi-benefit. The lead-free piezoelectric ceramic (KNSN3) exhibited a different electrostatic strain behavior from that of PZT and a very large strain due to the synergistic effect of defective dipoles and ferroelectric domains formed by the electric field (Figure 1). Even more surprisingly, KNSN3 achieved a low hysteresis monopole strain of 0.25% under the 20 kV/cm electric field commonly used in piezoelectric actuators, exceeding that of commercial PZT ceramics.

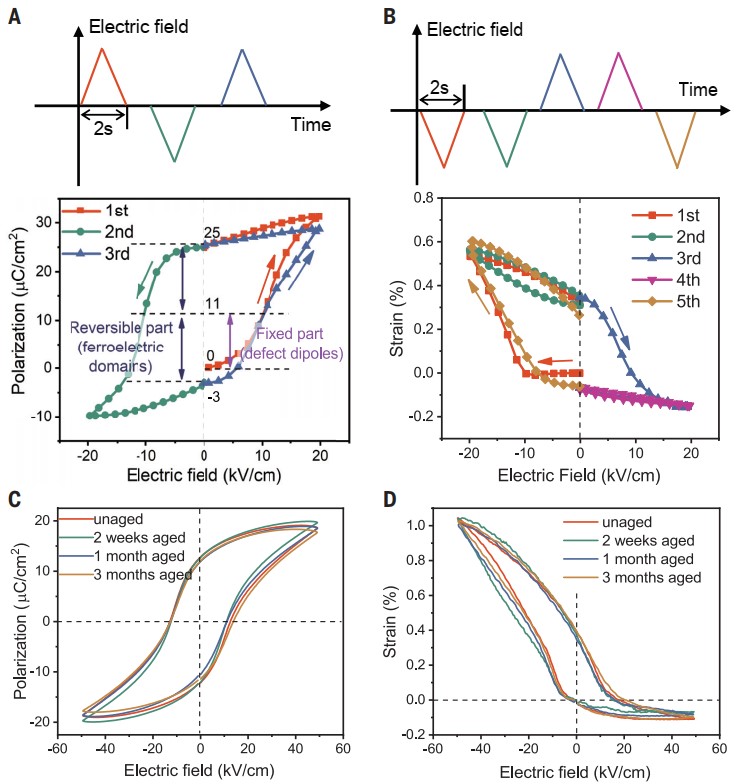

Figure 1 Comparison of the properties of commercial PZT ceramics and the lead-free piezoelectric ceramics (KNSN3) proposed in this paper

To explain the mechanism of the asymmetric strain profile in KNSN3, the researchers developed a theory related to defect dipoles and innovatively proposed a model for the coupling action of defect dipoles and ferroelectric domains. The results of electrical property tests, chemical composition analysis and first-principles calculations showed that the defect dipoles in KNSN3 ceramics were oriented along the external electric field during the initial electric field application, leading to significant fixed polarization (Figure 2). The lattice distortion induced by the oriented defect dipole under the electric field and the distortion induced by the ferroelectric domain flip interact with each other and together led to the asymmetric strain profile of the KNSN3 ceramics. The polarization and strain characteristics of KNSN3 remained stable during long aging (Figure 2C, D), indicating that the defective dipole can have excellent stability after being oriented under the initial electric field.

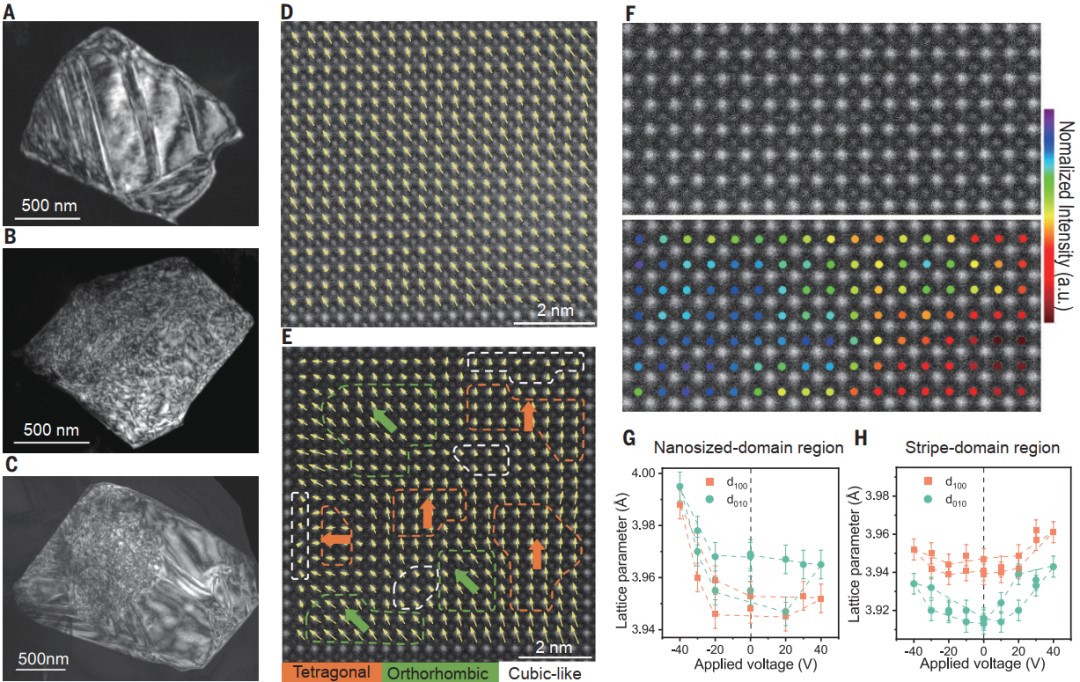

Figure 3. The TEM darkfield images, atomic-scale HAADF images and the evolution of interplanar spacing of {100} planes during in situ electric stimuli of KNSN3

By introducing defective dipoles and modulating the phase structure and ferroelectric domain structure, KNSN3 ceramics achieved large strains (up to 1.05% strain at 50 kV/cm electric field with an inverse piezoelectric coefficient of about 2100 pm/V); large strains with low hysteresis at low driving electric fields (up to 0.25% strain at 20 kV/cm electric field), exceeding PZT ceramics and other lead-free ceramics (Figure 4). In addition, KNSN3 had excellent fatigue resistance and temperature stability, showing great potential for applications in the field of piezoelectric ceramic actuators. This study paved the way for lead-free piezoelectric ceramics to replace commercial PZTs, and also provided a new perspective on the design of high-performance piezoelectric ceramic materials.

Figure 2. P-E behavior and S-E behavior of the initial few unipolar electric field applications on a fresh KNSN3 sample and during a 3-month aging process, respectively

The presence of striped domains and nanodomains in the KNSN3 ceramics was observed by transmission electron microscopy and spherical aberration correction transmission electron microscopy, with homogeneous orthogonal phases in the striped domain regions and the coexistence of multiple ferroelectric phases in the nanodomain regions. The nanodomain regions were rich in K+/Na+ vacancies, and the in situ transmission electron microscopy results showed that the lattice strain pattern under the electric field was similar to the macroscopic strain profile (Figure 3). Since the multiphase coexistence decreased the potential barrier for polarization deflection, the defect dipoles can be oriented by the initially applied external electric field in the nanodomain regions, which further demonstrated that large polar defect dipoles can induce significant lattice distortions.

Figure 4. Excellent electrostrain properties of KNSN3

Binquan Wang and Jie Wang, Ph.D. students from the School of Materials Science and Engineering of Shanghai Jiao Tong University, researcher Haosu Luo from the Shanghai Institute of Silicate, Chinese Academy of Sciences, and Professor Dwight Viehland from Virginia Tech, USA, also participated in this research work. This research was supported by the National Natural Science Foundation of China (52032012), the Key Basic Research Project of Shanghai Science and Technology Commission (20JC1415000), and the State Key Laboratory of Metal Matrix Composites, Shanghai Jiao Tong University - Maanshan Rail Transit Joint Fund.