Prof. Tao Deng and Wen Shang's group at the School of Materials Science and Engineering, Shanghai Jiao Tong University, together with Prof. Michael D. Dickey's group at North Carolina State University and Dr. Jun Wang at the R&D Center of A123 Systems, have recently made an important breakthrough in the field of flexible packaging materials and technologies after more than three years of collaborative efforts. This work entitled "Liquid metal-based soft, hermetic, and wireless-communicable seals for stretchable systems" was published in Science.

This work solves the problem that traditional packaging materials cannot simultaneously possess stretchability and high gas tightness by constructing liquid metal-based flexible sealing composites supported by micron glass sphere arrays, and designs and constructs wireless-communicable, flexible packaging systems. Stable and reliable packaging of stretchable lithium-ion batteries, flexible gas-liquid phase change heat transfer devices, and multifunctional flexible devices are demonstrated, which indicates their promising applications in flexible energy, electronic information, and biomedical fields. Qingchen Shen, Modi Jiang, Ruitong Wang, Kexian Song, School of Materials Science and Engineering, Shanghai Jiao Tong University, and Man Hou Vong, Department of Chemical and Biomolecular Engineering, North Carolina State University, USA, are the co-first authors of the paper. Professor Tao Deng and Wen Shang, School of Materials Science and Engineering, Shanghai Jiao Tong University, Professor Michael D. Dickey, Department of Chemical and Biomolecular Engineering, North Carolina State University, USA, and Dr. Jun Wang at R&D Center of A123 Systems are the co-corresponding authors of the paper. Shanghai Jiao Tong University is the first unit of the paper.

Research from Prof. Tao Deng and Wen Shang's team published in Science

Flexible stretchable packaging materials and technology

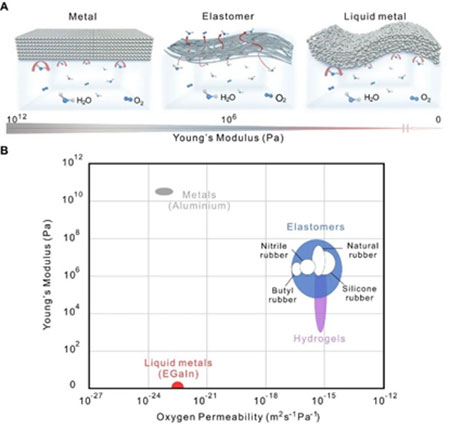

Figure 1. Performance comparison between liquid metal and other materials. (A) Schematic diagram of the comparative stretchability and gas tightness of metal, elastomer, and liquid metal. (B) Comparison of Young's modulus and oxygen permeability for various types of packaging materials. The red data points are the data of liquid metal-based sealing composites measured in this study.

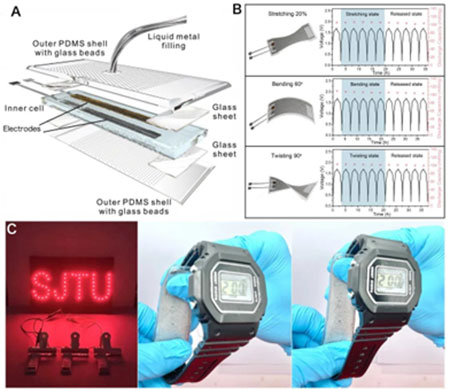

The liquid metal-based sealing composites were applied to encapsulate aqueous electrolyte-based stretchable lithium-ion batteries (Figure 2A, B). It was found that the reversible charging capacity of the encapsulated lithium-ion battery was 105.5 mAh/g under the natural unstretched state, and it could still maintain 72.5% of the initial capacity after 500 charge and discharge cycles, while the conventional elastomer-encapsulated battery completely failed after about 160 cycles. Under 20% of tensile strain, the encapsulated battery could maintain the capacity of 105.0 mAh/g, and the constant-current charge/discharge curve and the corresponding capacity remained almost unchanged under stretching, bending, and twisting deformation (Figure 2B). Such devices have great potential as energy storage components in stretchable electronics (Figure 2C).

Figure 2. Liquid metal-based sealing composites for packaging stretchable aqueous lithium-ion batteries. (A) Schematic diagram showing the structure of liquid metal-encapsulated stretchable aqueous lithium-ion battery. (B) Voltage curve (black curve) and discharging capacity (red dot data) of the encapsulated lithium-ion battery under continuous cyclic stretching (20%), bending (60°) and twisting (90°). (C) Encapsulated stretchable lithium-ion batteries used as energy storage components for power supply in practical applications. The operating photographs showing a light-emitting diode array (left), and an electronic watch powered by the encapsulated battery under unstretched (middle) and stretched (right) states.

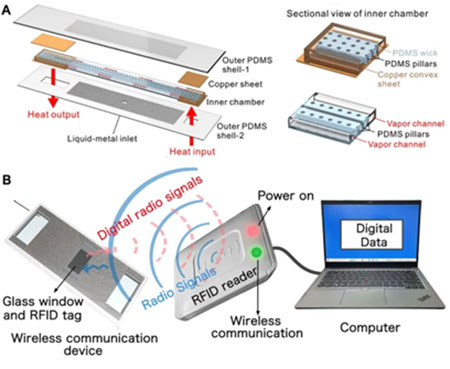

In addition, the research team also found that the liquid metal-based encapsulation composites also have excellent sealing performances for common organic solvents such as ethanol. They designed and prepared a stretchable gas-liquid phase change heat transfer device that utilizes ethanol as the working medium (Figure 3A). An effective thermal conductivity above 300 W/(m K) was stably achieved by the encapsulated device under stretching and heating. Such encapsulated heat transfer devices hold the promise for providing a new and reliable solution for thermal management of flexible electronics.

To address the restricted wireless communication capability arising from the electromagnetic shielding effect of liquid metals, the research team further proposed a separated structure design, by introducing electromagnetic signal transmission windows in the liquid metal-based encapsulation system, and thus endowed the encapsulated system with wireless communication functionalities while maintaining their original excellent stretchability and gas tightness (Figure 3B), thereby further expanding the application of liquid metal-based sealing composites in multifunctional electronic devices.

Figure 3. Liquid metal-based sealing composites applied for encapsulation of stretchable gas-liquid phase change heat transfer device and wireless-communicable sealing systems. (A) Schematic diagram showing overall and internal structure of the stretchable gas-liquid phase change heat transfer device encapsulated by liquid metal-based sealing composites. (B) Liquid metal-based encapsulation systems with wireless communication functionality. The introduction of electromagnetic wave signal transmission window in the encapsulation system realizes wireless communication between the radio frequency identification (RFID) tag and the RFID reader.

This work was supported by grants from the National Natural Science Foundation of China (51973109, 51873105), the Innovative Project of Shanghai Municipal Education Commission (2019-01-07-00-02-E00069), the Zhiyuan Fund of Shanghai Jiao Tong University, and the Scholarship for Study Abroad of Shanghai Jiao Tong University.