Recently, the research team led by Associate Professor Bing Ye of Shanghai Jiao Tong University (SJTU) collaborated with Ningbo Branch of China Academy of Ordnance Science, made major breakthroughs in the theoretical strengthening model of eutectic colony materials. The research paper entitled “Theoretical model of yield strength for eutectic colony microstructure materials”, is published in Scripta Materialia, an internationally renowned academic journal, and the paper link is https://doi.org/10.1016/j.scriptamat.2023.115443.

The most classic strengthening models in materials science include Hall-Petch grain boundary strengthening model ![]() proposed by British E.O. Hall and N.J. Petch, and Orowan precipitation strengthening model proposed by E. Orowan. Both models are not only simple, but also effective in predicting macroscopic mechanical properties from microstructure characteristics. However, it is still lacking the relevant model for the most common two-phase eutectic alloys in materials. This study combines the Brown model and the Taylor-Orowan equation, focusing on material parameters including volume fraction f and eutectic spacing λ. The eutectic structure strengthening model

proposed by British E.O. Hall and N.J. Petch, and Orowan precipitation strengthening model proposed by E. Orowan. Both models are not only simple, but also effective in predicting macroscopic mechanical properties from microstructure characteristics. However, it is still lacking the relevant model for the most common two-phase eutectic alloys in materials. This study combines the Brown model and the Taylor-Orowan equation, focusing on material parameters including volume fraction f and eutectic spacing λ. The eutectic structure strengthening model ![]() is first proposed based on theoretical derivation, and this theoretical model for eutectic microstructure is the last piece of puzzle in the field of strengthening mechanism. Also the model is validated by Al-Ce alloy data in our group and the medium entropy alloy reported in the literature. This model provides theoretical guide for further strengthening mechanism investigation and alloy development of eutectic alloys, and declares the direction for material parameters characterizing of eutectic alloy. Essentially, this theoretical model has broad application prospects.

is first proposed based on theoretical derivation, and this theoretical model for eutectic microstructure is the last piece of puzzle in the field of strengthening mechanism. Also the model is validated by Al-Ce alloy data in our group and the medium entropy alloy reported in the literature. This model provides theoretical guide for further strengthening mechanism investigation and alloy development of eutectic alloys, and declares the direction for material parameters characterizing of eutectic alloy. Essentially, this theoretical model has broad application prospects.

The strength of materials represents enhancement of the resistance to plastic deformation. There are four types of strengthening of metallic materials including Hall-Petch strengthening, solid solution strengthening, second phase strengthening and work hardening. Hall-Petch equation ![]() demonstrates a concise relationship between macroscopic mechanical strength and microstructure for the materials. The yield strength σys of the alloy is related to the physical constants k and grain size D. Second phase strengthening including precipitation and dispersion strengthening, is an extremely important type of strengthening in materials, and plays a primary role in understanding and development of high-strength aluminum alloys and steels over the last century. The eutectic morphology that is taught along with eutectic phase diagram in the introductory materials science and engineering course, is industrially and technological important. However, to the best of my knowledge, there is no appropriate model available to describe the strength contribution from eutectic microstructure.

demonstrates a concise relationship between macroscopic mechanical strength and microstructure for the materials. The yield strength σys of the alloy is related to the physical constants k and grain size D. Second phase strengthening including precipitation and dispersion strengthening, is an extremely important type of strengthening in materials, and plays a primary role in understanding and development of high-strength aluminum alloys and steels over the last century. The eutectic morphology that is taught along with eutectic phase diagram in the introductory materials science and engineering course, is industrially and technological important. However, to the best of my knowledge, there is no appropriate model available to describe the strength contribution from eutectic microstructure.

To solve the above challenges, our research team first adopts Eshelby's equivalent inclusion theory ![]() to obtain mean stress in the matrix

to obtain mean stress in the matrix ![]() . Following Tresca yield criterion, the yield stress of multiphase structure is expressed as

. Following Tresca yield criterion, the yield stress of multiphase structure is expressed as ![]() . Combining Taylor-Orowan's equation

. Combining Taylor-Orowan's equation ![]() from dislocation theory, the yield stress for eutectic colony microstructure materials is obtained as

from dislocation theory, the yield stress for eutectic colony microstructure materials is obtained as ![]() , or

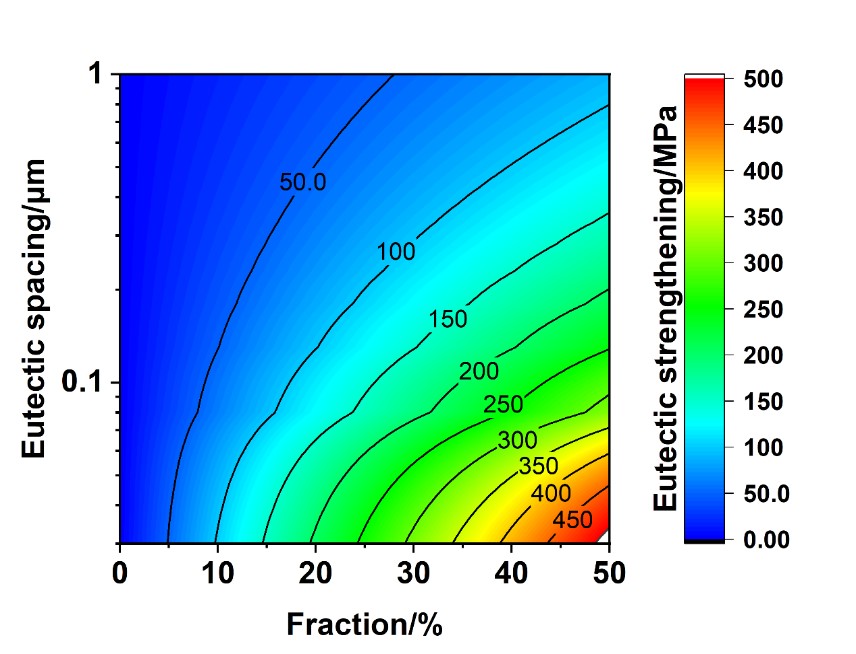

, or ![]() (Fig. 1). In this equation, G* is the effective shear modulus, kn is the shape factor related to microstructure morphology, f is the volume fraction of the second phase, and λ is eutectic spacing.

(Fig. 1). In this equation, G* is the effective shear modulus, kn is the shape factor related to microstructure morphology, f is the volume fraction of the second phase, and λ is eutectic spacing.

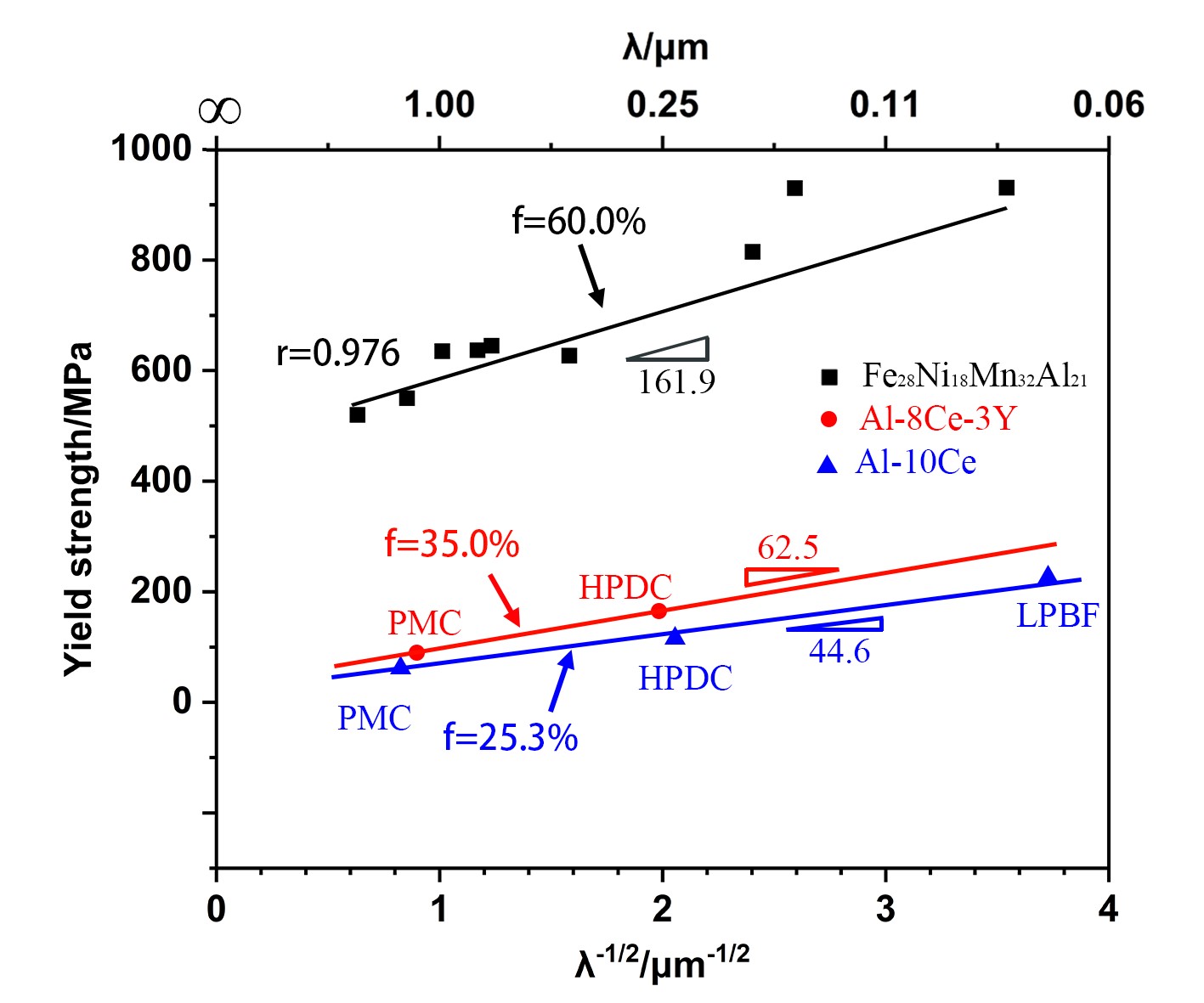

The theoretical yield strength model proposed in this article for eutectic colony microstructure materials has the same concise and succinct form as the Hall-Petch equation and Orowan equation. The relationship is established between macroscopic mechanical properties and the microstructure characteristics such as eutectic spacing and volume fraction, and provides a quantitative relationship for the yield strength of eutectic structural alloys for the first time. Also it provides insights and design strategy for eutectic colony strengthening. Finally, the theoretical model has been verified based on data from our group and literature data on medium-entropy alloy (Fig. 2).

Shanghai Jiao Tong University is the first completion organization of this article, Ph.D. student Liyang Wang is the first author, and Prof. Bing Ye is the corresponding author. The main collaborators of the research work include Academician Wenjiang Ding of NERC-LAF, group leader and Prof. Wei Huang of Ningbo Branch of China Academy of Ordnance Science. This work was supported by the National Key Research and Development Project of China (Grant No. 2016YFB0301001).

Scripta Materialia is a sister journal of flagship material journal Acta Materialia, which reports original results rather than incremental research in the form of communication, focusing on the functional or mechanical behavior of metals, ceramics, and semiconductors.

Fig. 1 Schematic representation of eutectic strengthening related to eutectic spacing and volume fraction

Fig. 2 The relationship of yield stress and eutectic spacing of Al-Ce cast alloys and medium-entropy alloy.