Recently, Professor Wang Haowei's team from the School of Materials Science and Engineering at Shanghai Jiao Tong University achieved a significant breakthrough in the field of high fatigue-resistant 3D printing aluminum alloys. The related findings were published in the internationally renowned academic journal "Nature Materials" under the title "Achieving Ultrahigh Fatigue-Resistant AlSi10Mg Alloys by Additive Manufacturing." This work was completed in collaboration with Professor Lu Jian's team from City University of Hong Kong.

This research introduces a novel anti-fatigue mechanism for metals, where the 3D dual-phase cellular nanostructure formed due to rapid solidification during the 3D printing process effectively constrains dislocation movement, suppresses damage accumulation during fatigue cyclic loading, and thus delays the initiation of fatigue cracks. This mechanism can greatly enhance the materials’ fatigue resistance performance. By optimizing the material composition and printing process, the research team successfully fabricated TiB2-modified AlSi10Mg alloys with ultrahigh fatigue strength. The fatigue limit reached an ultrahigh 260 MPa (R=0.1), which is twice that of other 3D printing aluminum alloys and surpasses traditional forged aluminum alloys. The high fatigue-resistant 3D printing aluminum alloy developed by this team has been successfully applied to key components of aircraft and verified through overall lifespan experiments.

The research paper lists Shanghai Jiao Tong University as the first completion institution. The co-first authors include Dr. Dan Chengyi, Assistant Professor Cui Yuchi, Associate Professor Wu Yi and Professor Chen Zhe from the School of Materials Science and Engineering at Shanghai Jiao Tong University. Professor Chen Zhe from Shanghai Jiao Tong University and Academician Lu Jian from City University of Hong Kong are the corresponding co-authors. This work is a breakthrough based on the foundation of Shanghai Jiao Tong University's development of high-strength additive manufactured TiB2-modified AlSi10Mg alloys in 2017 (Acta Materialia 129, 2017, 183-193).

Statistics indicate that over 80% of failures in engineering structural components are attributed to material fatigue, posing a challenge in the engineering field for nearly two centuries. While 3D printing technology enables the rapid fabrication of lightweight structures with complex geometries, printing defects introduced during the process significantly reduce the fatigue strength of 3D printed materials, becoming the primary bottleneck limiting their applications. Enhancing the fatigue strength of 3D printed metal materials has been a long-standing focus and challenge in both academia and industry.

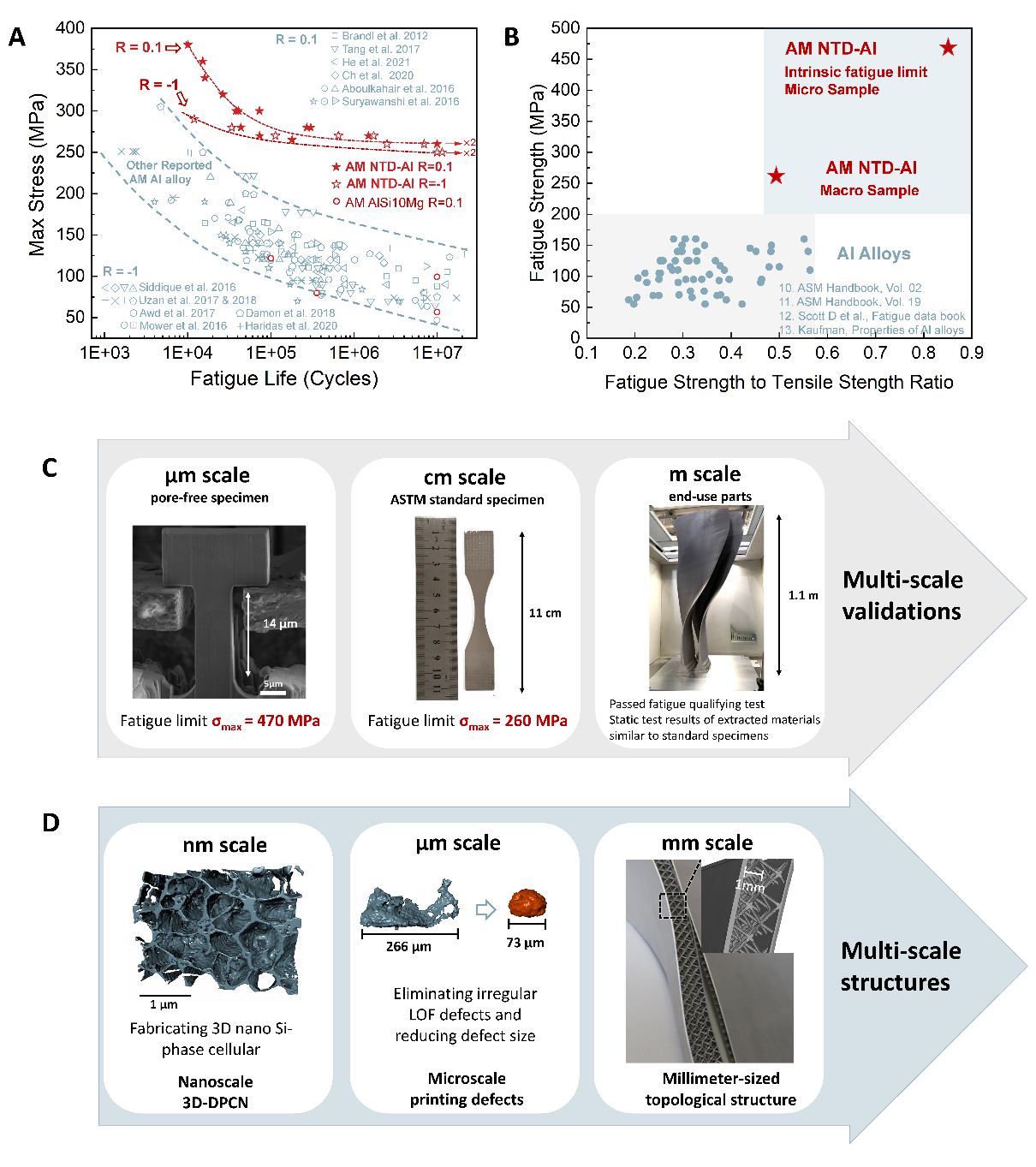

Fig. 1 Achieving high fatigue strength of the AM NTD-Al alloy. (A) Number of cycles to failure plotted against the maximum stress of AM NTD-Al (stress ratio (R) = 0.1 and -1) and AM AlSi10Mg (stress ratio (R) =0.1), compared with other reported AM AlSi10Mg and AlMgScZr alloys. (B) Fatigue limit to tensile strength ratio vs. fatigue strength of AM NTD-Al, compared with Al alloys, R = -1. (C) Multi-scale specimen validations for fatigue performances. (D) Multi-scale structures for performance improvement.

Professor Chen Zhe and Dr. Dan Chengyi, among others, conducted a cross-scale structural composition optimization and fatigue performance characterization of 3D printed AlSi10Mg alloy. Their research proposed, for the first time, that the continuous 3D dual-phase cellular nanostructure of the LPBF AM AlSi10Mg alloy is reluctant to fatigue by inhibiting localised damage accumulation and fatigue crack initiation. The team used FIB processing to prepare micrometer-sized fatigue samples without printing defects. Through in-situ fatigue experiments using a nanoindentation instrument, they demonstrated that the 3D dual-phase cellular nanostructure in 3D printed AlSi10Mg alloy can effectively limit dislocation movement, suppress fatigue damage accumulation, and inhibit the initiation of fatigue cracks. The fatigue limit of the micrometer-sized samples reached over 80% of the tensile strength (470 MPa).

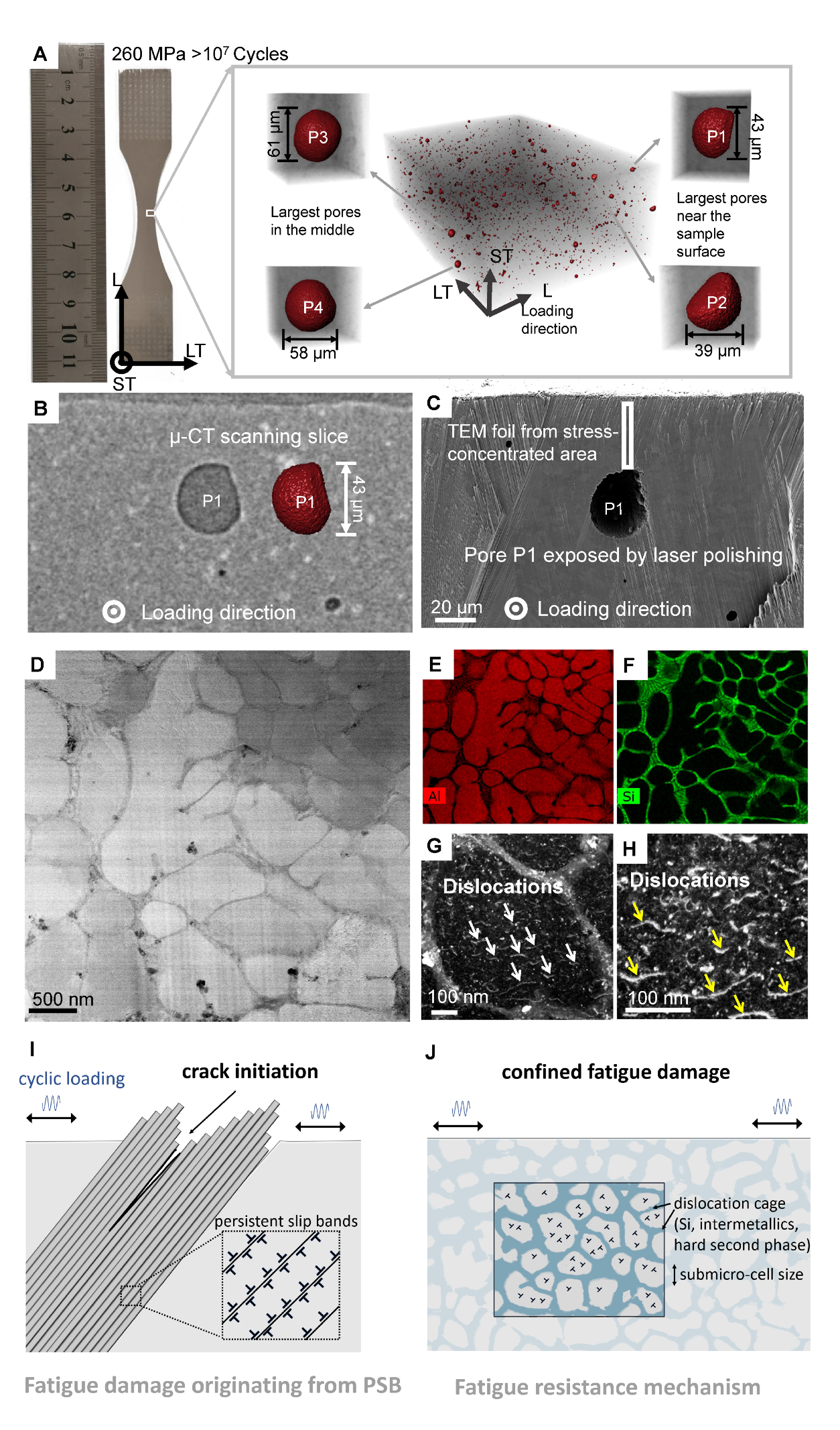

Based on this principle, the research team refined the material's composition by incorporating TiB2 nucleating nanoparticles into the AlSi10Mg alloy powders. The addition of TiB2 nanoparticles helped eliminate LOF defects and reduce the size of printing pores. This resulted in reduced stress concentration around printing defects, consequently enhancing the fatigue performance of bulk TiB2-modified AlSi10Mg alloys. The fatigue limit of bulk TiB2-modified AlSi10Mg alloys could reach 260 MPa, close to half of the tensile strength, making it twice that of other 3D printing aluminum alloys. The fatigued region of the sample was analyzed using μ-CT, revealing no evident cracks or discernible alterations in defect attributes, encompassing pore size, morphology, and distribution. Furthermore, the 3D dual-phase cellular nanostructure remained intact after the fatigue test, affirming the exceptional fatigue-resistant capability of the 3D dual-phase cellular nanostructure.

The research indicates that the 3D dual-phase cellular nanostructure shows a characteristic fatigue response with no shearing or damage accumulation below the critical stress, which has significant advantages in industry compared with conventional alloys where the unpredictability of fatigue damage accumulation raises great uncertainty. By eliminating or controlling printing defects within the submicron size range through technological innovations, the fatigue resistance of 3D printed AlSi10Mg alloy could be further enhanced. Moreover, this fatigue-resistant damage mechanism achieved through 3D printing can be extended to the design of other fatigue-resistant dual/multiphase alloy systems and other 3D printing preparation techniques.

Special thanks are extended to TESCAN China and Carl ZEISS for their technical support in this research, as well as Shanghai Huayuan Testing Co., Ltd. for their in-situ experimental support. This research was funded by projects such as the National Natural Science Foundation of China (51971137, 52101043, 52101179).

The Institute of Special Materials at the School of Materials Science and Engineering of Shanghai Jiao Tong University is an essential part of the State Key Lab of Metal Matrix Composites. Headed by Professor Wang Haowei, it has established multiple joint laboratories with internationally renowned universities and large enterprises. The institute primarily engages in the research and development of novel special materials, including their design, fabrication, and deformation technologies. Over the years, it has undertaken more than fifty major national projects, published nearly 300 academic research papers in both domestic and international scholarly journals, and obtained over 100 authorized Chinese national invention patents. It has been honored with several awards, including the First Prize for Technological Invention from the Ministry of Education, the First Prize for Technological Invention from the Shanghai Municipal Government, and the First Prize for Technological Invention from the China Nonferrous Metals Industry.

Fig. 4 Fatigue resistance mechanism investigation on the specimen after 107 fatigue cycles at a maximum stress of 260 MPa (R = 0.1). (A) No obvious cracks were observed in the specimen after fatigue testing; no cracks emerged from the largest pores (P1-P4); P1 and P2 were located close to the sample surface while P3 and P4 were in the middle of the sample. (B) μ-CT scanning cross-section of P1. (C) Locating and exposing the cross-section of P1 by μ-CT-guided laser polishing. (D) TEM characterisation of intact Si cellular structure in the region next to P1 (TEM foil lifted out from the rectangular region in Fig. 4C). (E-F) EDS maps illustrating the distribution Al and Si elements. (G-H) Individual dislocations distributed inside one Si nano-cellular structure.