Regions with sharp local textures, i.e., macrozones, are common microstructural inhomogeneities in titanium (Ti) alloys that significantly reduce the fatigue resistance of Ti alloy parts. However, owing to the narrow process window of Ti alloy and complex microstructural evolutions (e.g., dynamic recovery, dynamic recrystallization, variant selection and twinning) during the thermomechanical processing, the macrozones inherited from the wrought forging stock are difficult to eliminate. Based on the near α Ti alloys, the research group of Profs. Zhenshan Cui and Haiming Zhang (School of Materials Science and Engineering, Shanghai Jiaotong University) focuses on the elimination of macrozones. Relevant research achievements were published in Acta Materialia. PhD candidate Shuai Xu is the first author, and associate Professor Haiming Zhang is the corresponding author of the article. Other co-authors of the articles are the Prof. Zhenshan Cui from Shanghai Jiaotong University, Prof. Namin Xiao from Aero Engine Corporation of China, associate Prof. Risheng Qiu from Chongqing University and Prof. Mingwang Fu from Hong Kong Polytechnic University.

Paper Link:

https://doi.org/10.1016/j.actamat.2023.119339

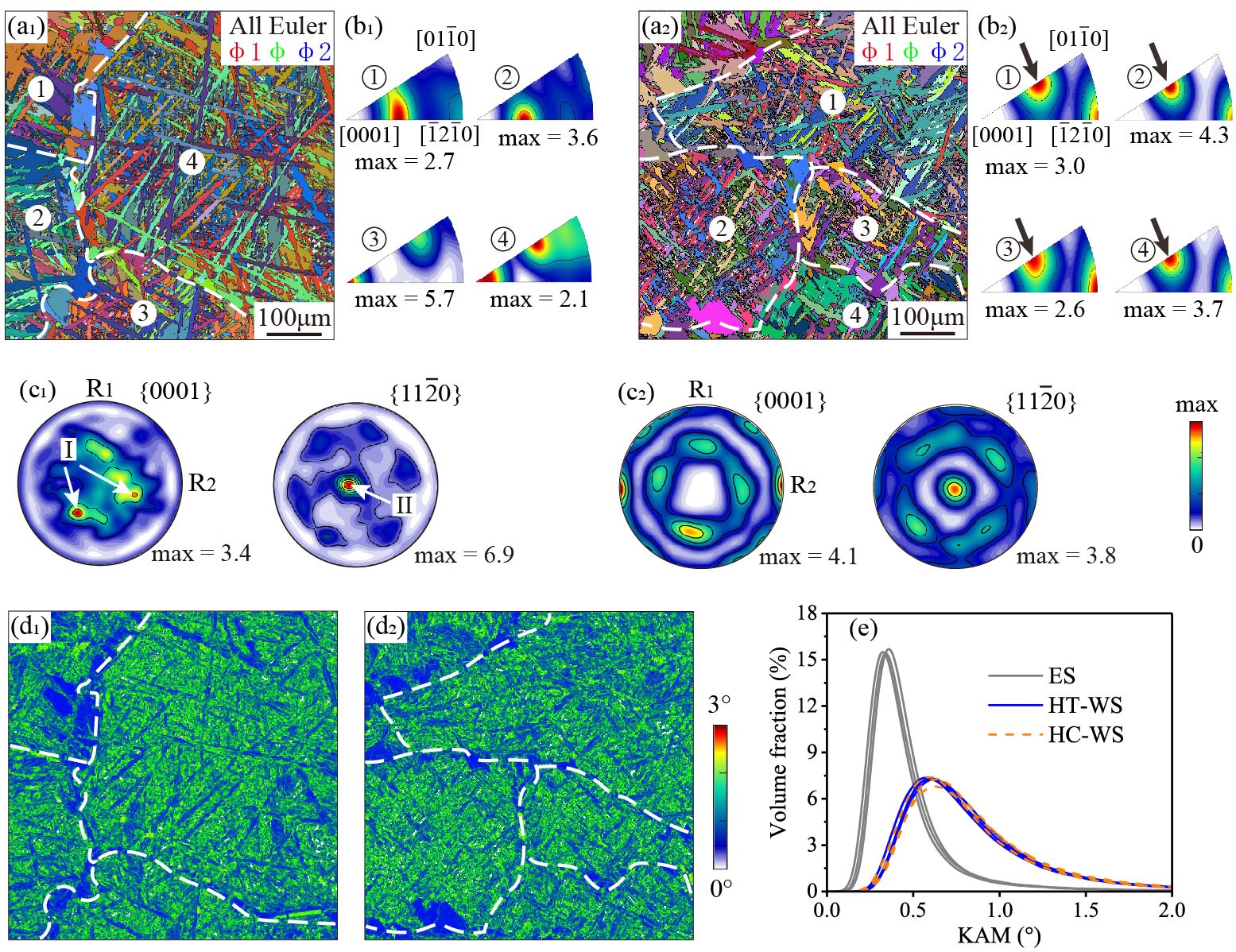

In the research, a two-stage thermomechanical processing i.e., heat treatment in the β phase region followed by hot compression in the α phase region, was proposed to eliminate the macrozones for near α Ti alloys. Multiscale microstructure characterization and full-field crystal plasticity modeling were conducted to uncover the underlying mechanisms. The wrought materials with macrozones were first heat treated in the β phase region followed by a quick air cooling, obtaining the heat treated Widmannstätten structure (HT-WS). Due to the lattice mismatch between the β and αs phases, a large number of nano-defects, e.g., dislocations and nano-twins, were generated in the HT-WS. Then the HT-WS samples were subjected to the hot-compression ( = 50%) in the α phase region. The abundant nano-defects in HT-WS can promote the geometric dynamic recrystallization even under a limited deformation ( = 30%), resulting in a sufficient grain refinement. The grain boundary sliding can be activated for the refined α grains during the plastic deformation. And the grain boundary sliding can increase the randomness of grain rotations, thus eliminating macrozones. The hot-compression Widmannstätten structure (HC-WS) also contains plenty of nano-defects, however, HC-WS has a strong deformation texture. And the lamellar α grains with AD// orientation which exhibit a high relative volume fraction in HC-WS samples were difficult to be refined through GDRX. Thus, the HT-WS samples can obtain a uniform fine-grain structure with a very weak texture while the HC-WS samples cannot after the hot-compression in α phase region.

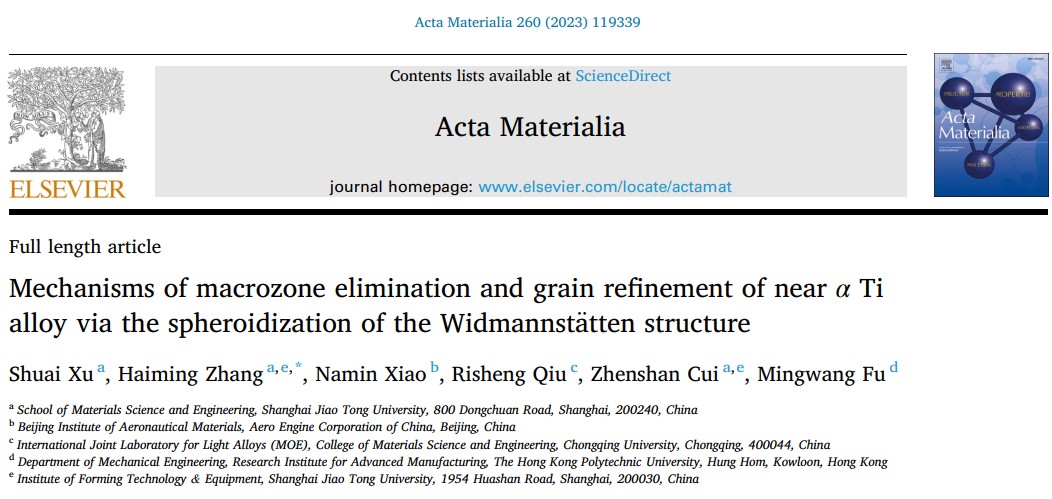

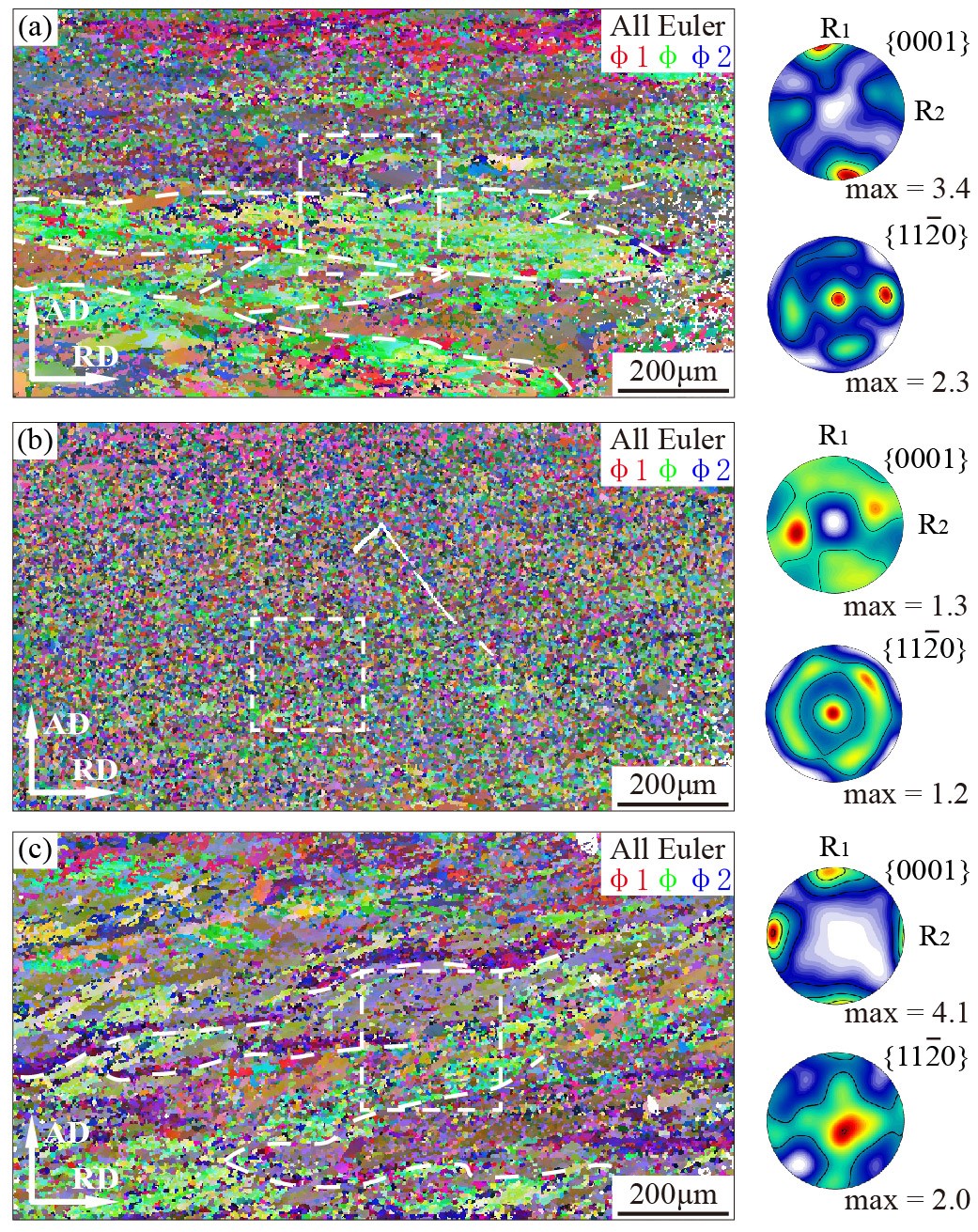

Fig. 1. Large-scale EBSD characterization of the as-received material revealing sharp texture heterogeneities, i.e., macrozones.

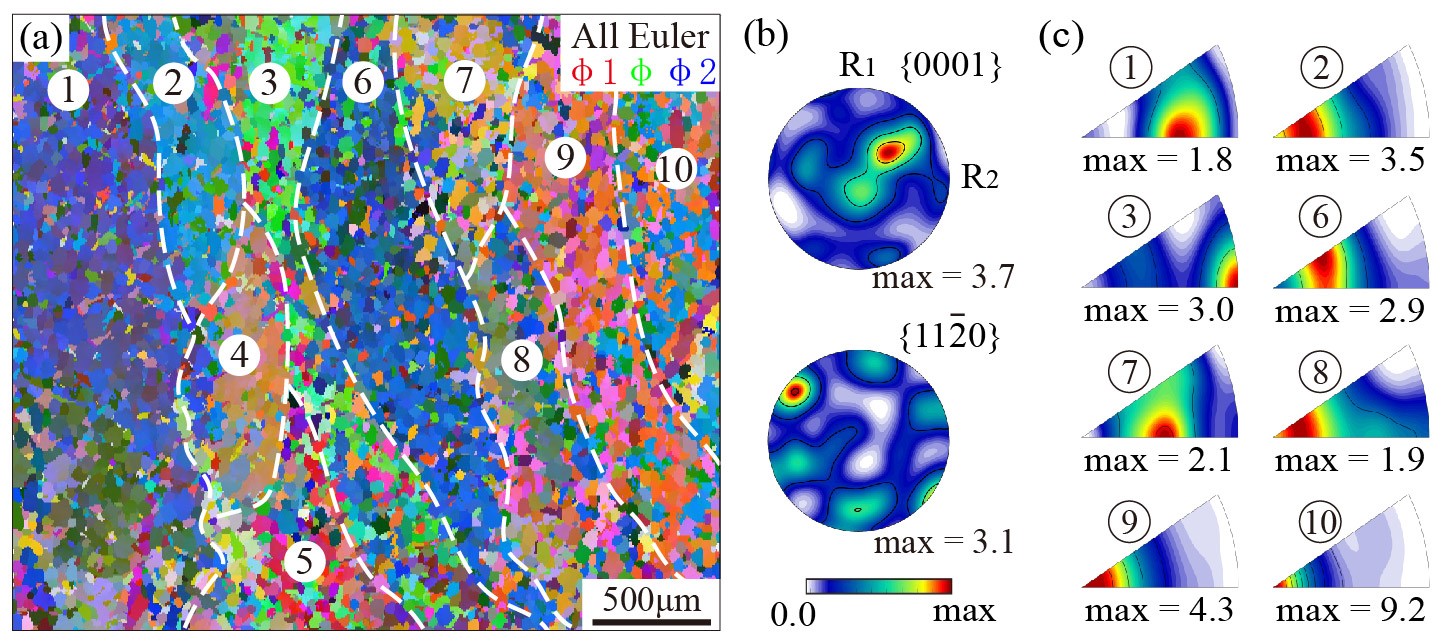

Fig. 2. Subscript 1 is heat treated Widmannstätten structure (HT-WS), Subscript 2 is hot-compression Widmannstätten structure (HC-WS. (a) all-Euler maps, (b) AD-IPFs showing the local texture distribution of clusters, (c) and pole figures (PFs) measured by XRD showing the macro-texture, (d) KAM maps, (e) KAM distribution in the samples with different microstructures.

Fig. 3. TEM observations of (a - d) the HC-WS and (e - i) HT-WS samples.

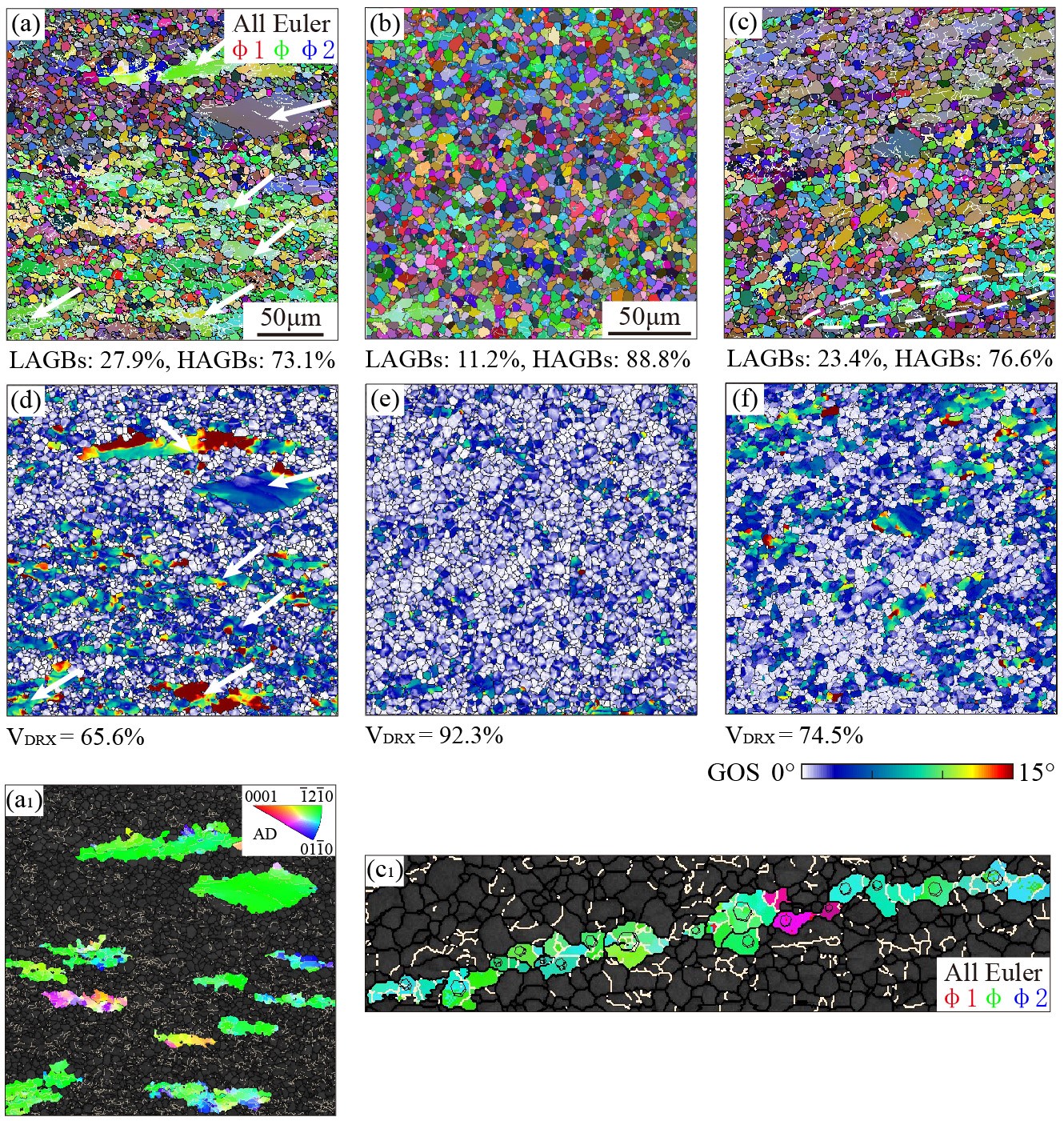

Fig. 4. Microstructures of the compressed HC-WS and HT-WS samples. (a) The HC-WS sample compressed by 50%, macrozones still exit; (b) the HT-WS samples compressed by 50%, macrozones are completely eliminated; (c) the HT-WS samples compressed by 30%, the size of macrozones in Fig. 4c is less than that in Fig. 4a.

Fig. 5. High-resolution EBSD characterizations of the areas marked by a white dashed rectangle in Fig. 4. (a, d) HC-WS sample compressed by 50%, (a1) un-refined coarse grains in 50% compressed HC-WS sample mostly exhibti a orientation; (b, e) HT-WS sample compressed by 50%, which achieves a sufficient DRX and grain refienment; (c, f) HT-WS sample compressed by 30%; (c1) GDRX in 30% compressed HT-WS sample.

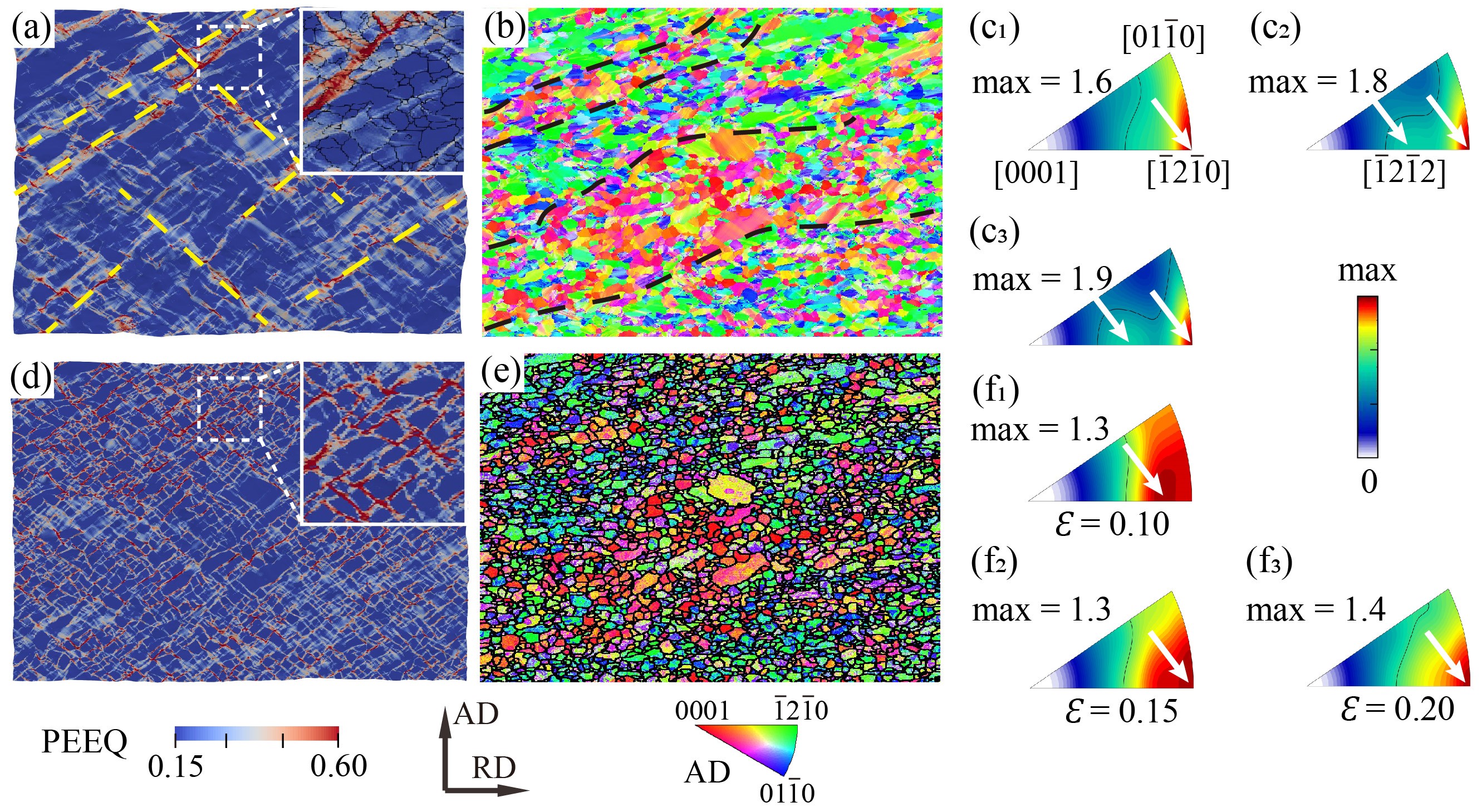

Fig. 6. Full-field CPSM simulation results of the HC-WS sample revealing the orientation dependence of plastic deformation. (a) OIM of the RVE used for the simulation, (b) equivalent strain distribution, (c, d) shear strain distributions of the basal and prismatic slips.

Fig. 7. CPSM simulation results: (a - c) CPSM simulation considering only dislocation slip in the interior of grains, which shows that the dislocation slip can exacerbate the uneven distribution of local orientation; (d - f) considering both slip and superplasticity in terms of grain boundary sliding, which shows that the grain boundary sliding can suppresse the formation of macrozones.