Background

The strength-toughness tradeoff has been a longstanding issue towards the development of high-performance metal matrix composites (MMCs). In traditional metal matrix composites, the incorporation of hard and brittle ceramic reinforcements endows the composites with enhanced modulus and strength. However, associated severe strain localization and stress concentration in the composites deteriorate the plasticity and toughness. One potential solution involves the utilization of reinforcements that concurrently demonstrate outstanding intrinsic mechanical properties and deformability. Shape memory ceramics (SMCs) emerge as a representative category of deformable reinforcements with high modulus and strength. When subjected to temperature or stress field, shape memory ceramics can undergo a reversible phase transformation between the tetragonal and monoclinic phases, resulting in considerable lattice strain of ~10% (Science 341, 1505-1508, 2013).

Introduction

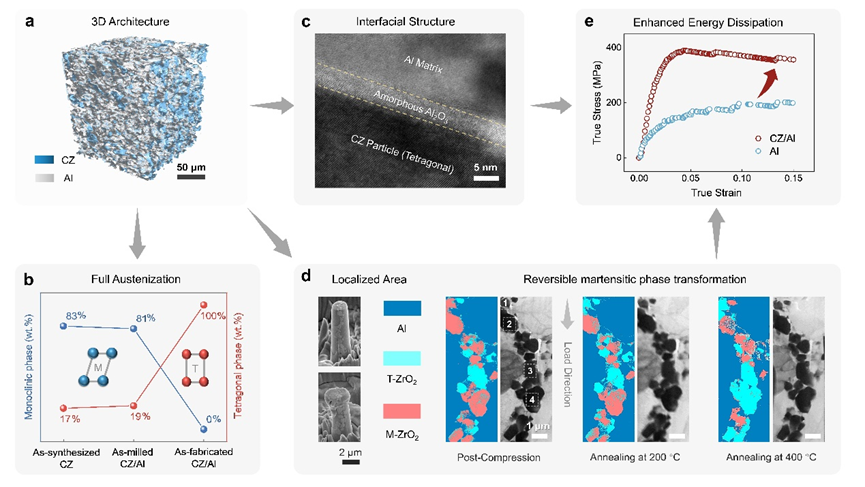

Prof. Qiang Guo, together with his colleagues from the State Key Laboratory of Metal Matrix Composites at Shanghai Jiao Tong University and his collaborator from Nanyang Technological University in Singapore, realized the reversible phase transformation of shape memory ceramics in metal matrix composites. The research team employed a cerium-doped zirconia (CZ) reinforced aluminum (Al) matrix composite as a model material, and both macroscopic and microscopic mechanical tests revealed more than doubled compressive strength and energy absorbance of the composites as compared with pure Al. Full austenitization in the CZ reinforcements was achieved when they were constrained by the Al matrix, and reversible martensitic transformation triggered by thermal or stress stimuli was observed in the composite micro-pillars without causing fracture in the composite. Combining precession electron diffraction (PED) technique and X-ray computed tomography microscopy (XRT), these results were interpreted by the strong geometric confinement offered by the Al matrix, the robust CZ/Al interface and the local three-dimensional particle network/force-chain configuration that effectively transferred mechanical loads, and the decent flowability of the matrix that accommodated the volume change during phase transformation. The corresponding finding, entitled "Realizing reversible phase transformation of shape memory ceramics constrained in aluminum," was published in Nature Communications.

Paper link:

https://doi.org/10.1038/s41467-023-42815-0

Research Content

Figure. A phase-transforming ceramic rendering strong-and-tough metal matrix composite (CZ/Al). (a) High-resolution X-ray computed tomography microscopy (XRT) volume renderings of CZ/Al composites. (b) Phase constitution at room temperature (25°C) measured by X-ray diffraction (XRD), where T and M represent tetragonal and monoclinic structure, respectively. (c) High-resolution transmission electron microscopy (TEM) analysis of the interface between CZ and Al. (d) Scanning electron microscopy (SEM) images of pre-compression (up) and post-compression (down) CZ/Al micro-pillar from localized area; precession electron diffraction (PED) bright-field image and phase maps of the sample at the states of a post-compression (25°C), after annealing at 200°C, and 400°C. (e) True compressive stress-strain curves of CZ/Al composite and pure Al.

Conclusion

This work has revealed the reversible phase transformation capability of shape memory ceramics in metal matrix composites, validating the feasibility of utilizing phase-transformable ceramics to address the strength-toughness tradeoff therein. From a structural load-bearing perspective, in comparison to traditional non-deformable reinforcements, the lattice strain induced by the phase transformation of ceramics can coordinate the deformation of the reinforcement-matrix, rapidly transferring external stress throughout the composites and avoiding stress concentration. Simultaneously, elastic strain energy may be additionally dissipated by phase transformation, thereby strengthening and toughening the composites. On the other hand, achieving reversible phase transformation of ceramics in lightweight metal matrix composites may tremendously extend the application arena of these smart composites to sensors, actuators, and damping devices that require lightweight, high strength, and multi-functionality.

Corresponding Authors

Di Zhang, Qiang Guo

State Key Lab of Metal Matrix Composites, Shanghai Jiao Tong University, 800 Dongchuan Road, Shanghai, 200240, China.

Chee Lip Gan

School of Materials Science and Engineering, Nanyang Technological University, 639798, Singapore