Background

The strength-toughness tradeoff has been a longstanding issue towards the development of high-performance metal matrix composites (MMCs). In traditional metal matrix composites, the reinforcements are randomly and uniformly dispersed within the metal matrix, endowing the composites with enhanced modulus and strength. However, the resulting severe strain localization and stress concentration in the composites would deteriorate the plasticity and toughness. One potential solution involves the bioinspired microstructure design. Biological structural materials can achieve both high strength and high toughness as a result of their exquisite microstructures. Inspired by the nanolaminated structure adopted by nacre, the research group have conducted a lot of work on nanolaminated metal matrix composites to achieve high strength, high modulus, and high toughness simultaneously.

Introduction

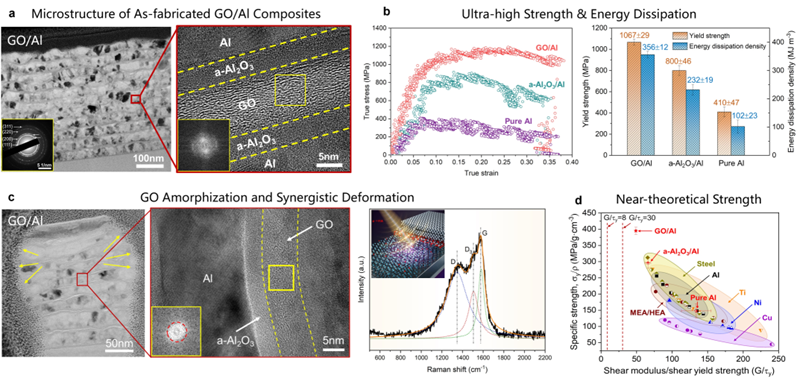

Prof. Qiang Guo, together with his colleagues from the State Key Laboratory of Metal Matrix Composites at Shanghai Jiao Tong University and his collaborator from the Korea Advanced Institute of Science and Technology (KAIST) in Korea, realized ultra-high compressive strength (over 1 GPa) while retaining excellent plastic deformability in Al-based composite nanolaminates. The research team fabricated graphene oxide (GO)-Al composite nanolaminates with Al lamella thickness of 30 nm via the alternating sputter deposition of Al nano-lamella and spin-coating of GO nanosheets. Micro-compression tests revealed the strength and energy dissipation density are increased by 1.6 and 2.5 times compared to those of pure aluminum matrix, indicative of excellent combination of the strength and toughness. Combining high-resolution transmission electron microscopy (HRTEM), Raman spectroscopy & scanning electron microscopy (Raman & SEM) and molecular dynamics simulation (MD), these results were interpreted by the strong blocking effect of the interface on dislocation nucleation and propagation, the stress/strain-induced crystalline-to-amorphous transition of graphene oxide, and the synergistic deformation between Al nano-lamellas and the GO layers.

The corresponding finding, entitled "Ultra-strong and deformable aluminum based composite nanolaminates with transformable binary intergranular films," was published in Nano Letters.

Paper link:

https://pubs.acs.org/doi/10.1021/acs.nanolett.3c04052

Figure. The microstructure and properties of graphene oxide (GO)-Al composite nanolaminates. (a) Cross-section TEM image of GO-Al composite nanolaminates, and the corresponding high-resolution TEM (HRTEM) image at the composite interface. (b) True stress-true strain curves of GO-Al nanopillars and the control groups. (c) Cross-section TEM image and the corresponding HRTEM image at the interface, as well as Raman spectrum of deformed GO-Al nanopillars. (d) Specific yield strength (sy/r) vs. shear modulus/shear yield strength (G/ty) of GO-Al nanolaminates as compared with those of reported high-strength nanocrystalline metals.

This work has revealed that a new energy dissipation mechanism of graphene oxide amorphization can be activated in graphene oxide-Al composite nanolaminates when the characteristic scale of the metal nano-lamella is reduced to be comparable to that of the graphene multilayers. The graphene oxide amorphization promotes the synergistic deformation between the graphene oxide and Al matrix, avoiding the stress concentration at the interface and consequently achieving a synergistic enhancement of strength and toughness. This work also validates the feasibility of achieving extreme performance through extreme dimension design in nanolaminated metal matrix composites.

Corresponding Authors

Di Zhang, Qiang Guo

State Key Lab of Metal Matrix Composites, Shanghai Jiao Tong University, 800 Dongchuan Road, Shanghai, 200240, China.

Seunghwa Ryu

Department of Mechanical Engineering and KI for the NanoCentury, Korea Advanced Institute of Science and Technology, Daejeon, Republic of Korea, 34141.