Recently, Prof. Guohua Wu's group made important progress in optimizing the strength-ductility trade-off in wrought Al-Cu-Li alloys. The results entitled ‘Achieving superior strength-ductility balance by tailoring dislocation density and shearable GP zone of extruded Al-Cu-Li Alloy’, were published in the International Journal of Plasticity which is one of the top journals in the field of plastic deformation of materials (the link is https://www.sciencedirect.com/science/article/pii/S0749641924002626). Prof. Guohua Wu and Assistant research fellow Xin Tong are the co-corresponding authors, and the first author is Doctoral candidate Xuanxi Xu. Associate Prof. Cunlong Wang from Jiangsu University is one of the co-authors. This work is supported by the National Natural Science Foundation of China.

Al-Li alloys are characterized by low density, high specific strength and stiffness, and excellent corrosion resistance, making them promising for applications in aerospace and underwater domains. The addition of 1 wt% Li to Al alloy can reduce the alloy density by 3% and increase the stiffness by 6%. Typical third-generation high-strength wrought Al-Li alloys, such as 2050, 2195, and 2198, are commonly utilized in critical load-bearing structures, including aircraft skins, frames, and stringers. The conventional thermomechanical treatment (T8 treatment) is often employed to introduce dislocations into the alloy matrix, promoting the precipitation of T1 strengthening phases that effectively pin dislocations during deformation. However, high-strength Al-Li alloys under T8 treatment often exhibit low ductility, presenting challenges in achieving a balance between strength and ductility, thereby limiting their application in critical aerospace fields.

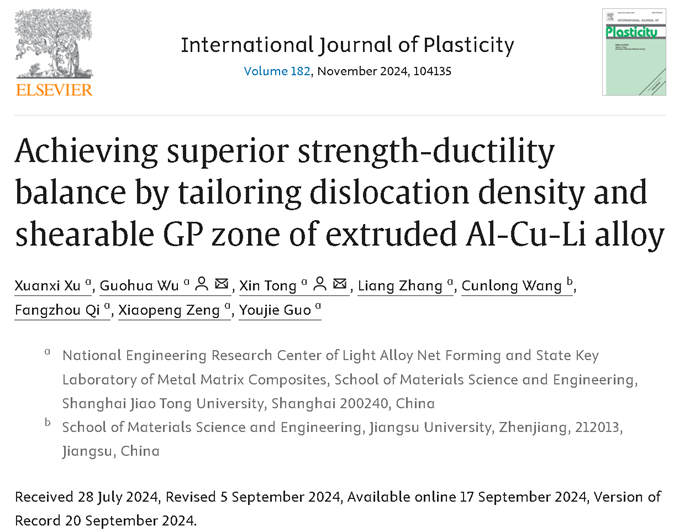

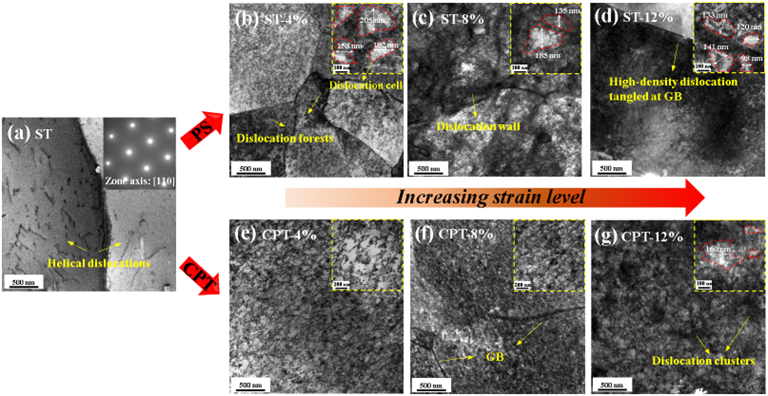

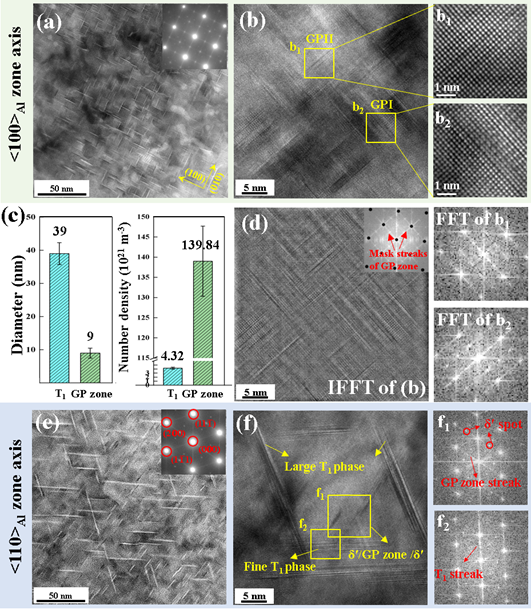

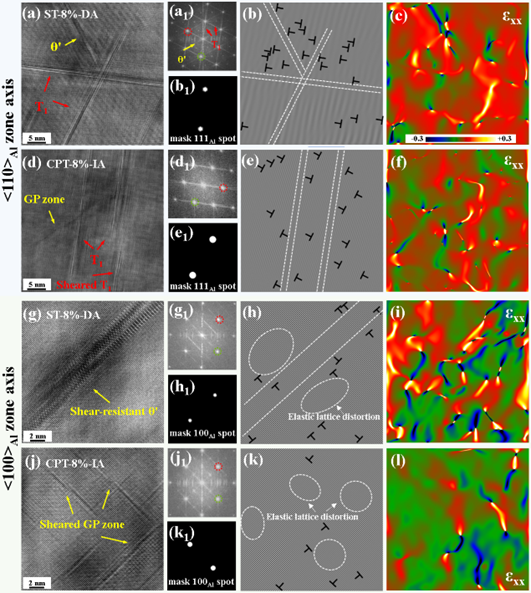

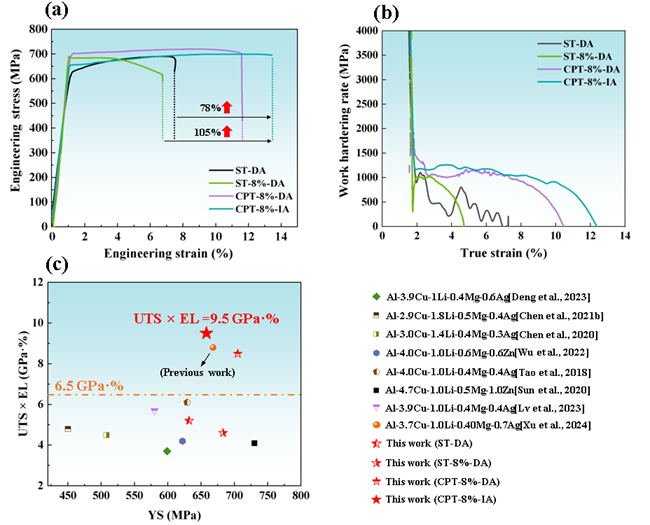

To address this dilemma, Prof. Guohua Wu's group developed an innovative thermomechanical treatment for extruded Al-3.5Cu-1Li alloys, introducing a pre-aging treatment before pre-stretching to facilitate the formation of metastable GP zones. This approach alleviates localized stress concentration caused by dislocation entanglement during pre-stretching, resulting in a uniform dislocation distribution. Subsequently, low-temperature interrupted aging leads to the coexistence of GP zones (a few nanometers) and T1 phases (tens of nanometers), creating a multi-scale heterogeneous microstructure. The results revealed that this unique multi-scale heterogeneous structure significantly enhances dislocation cross-slip and improves strain hardening capability, leading to a more uniform dislocation distribution during plastic deformation, as compared to the traditional T8-treated alloys. This novel strategy doubles the elongation while maintaining high yield strength, achieving exceptional mechanical properties (yield strength: 657 MPa, tensile strength: 700 MPa, elongation: 13.5%), thereby overcoming key bottlenecks in the strength-ductility trade-off in wrought Al-Cu-Li alloys. Based on the microstructural evolution during plastic deformation, Prof. Guohua Wu's group developed a precipitate-dislocation interaction model that elucidates the toughening mechanisms in wrought Al-Cu-Li alloys. The above findings provide a theoretical foundation for the development of high-performance wrought Al-Cu-Li materials.

In recent years, with the support of Academician Wenjiang Ding, Prof. Guohua Wu's group has made a series of research achievements in the development, preparation, and forming of high-performance Al-Li alloys, aiming to promote the advancement and application of these materials in China.

Fig. 1 The effect of novel thermomechanical treatment on dislocation distribution.

Fig. 2 The morphology of precipitates after interrupted ageing.

Fig. 3 The interaction between dislocation and precipitate in a tensile-fractured sample.

Fig. 4 The effect of the microstructure formed in the novel thermomechanical treatment on the strain distribution.

Fig. 5 Comparison of experimental results obtained in this study with the reported data for extruded Al-Cu-Li alloys in the literature.

Author: Xin Tong