In response to the global trends of carbon neutrality and energy conservation, the demand for new energy vehicles (NEVs) has surged, becoming a driving force behind the transformation of the automotive industry. As the industry embraces the waves of electrification and lightweighting, the NEV sector is witnessing unprecedented growth opportunities, while also placing higher innovation demands on high-performance lightweight alloy materials. Against this backdrop, CHANGAN Automobile has actively responded to the national strategic call, accelerating its pace of technological innovation and committing to the development of "new products and new ecosystems" as part of its green mobility solutions.

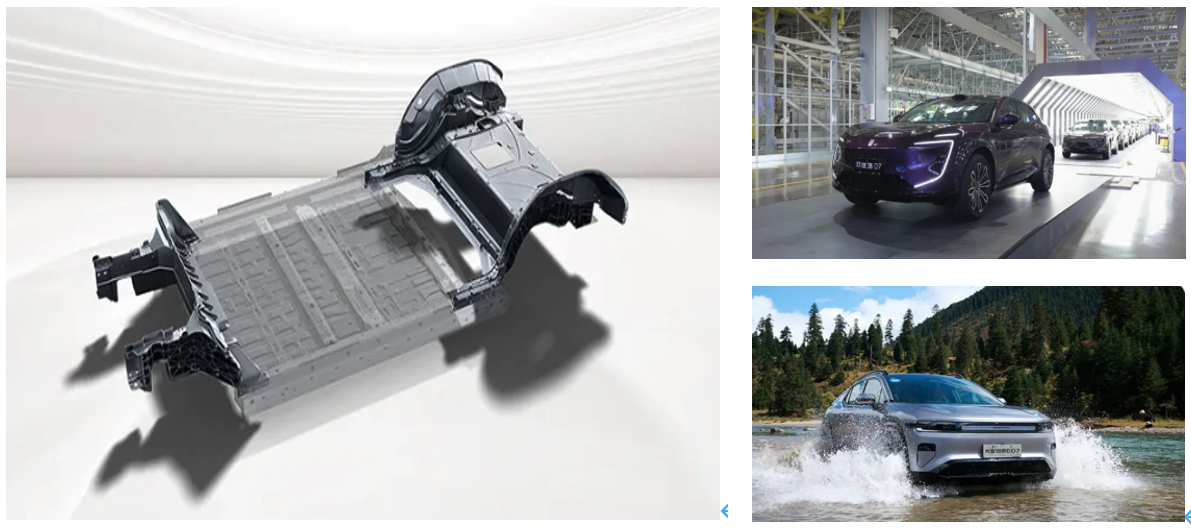

From October 18 to 21, 2024, the Fourth CHANGAN Automobile Technology and Ecosystem Conference was successfully held at CHANGAN’s Digital Intelligence Factory. The conference, themed “New Cars, New Ecosystem,” showcased the company’s latest research achievements and technological breakthroughs in the field of new energy vehicles. Among the highlights were the Avatr 07 and CHANGAN Qiyuan E07, two new energy vehicle models that feature large integrated die-casting components at the front and rear of their bodies. These components are made from a new heat-free treatment die-cast aluminum alloy material jointly developed by Academician Wenjiang Ding and Professor Liming Peng’s team at the Light Alloy Engineering Center of Shanghai Jiao Tong University, in collaboration with Fengyang Aiersi Light Alloy Precision Molding Co., Ltd. This innovative material application not only achieves the goal of vehicle lightweighting but also significantly enhances the vehicle's safety and crash protection capabilities.

According to Academician Wenjiang Ding and Professor Liming Peng’s team, the heat-free treatment die-cast aluminum alloy material applied in CHANGAN vehicles improves flowability by more than 15% compared to similar materials, while the strength-to-plasticity ratio is increased by over 30%. This not only helps to reduce vehicle weight and optimize the vehicle’s structural design but also ensures safety and reliability under extreme conditions. Additionally, the team has successfully developed two other alloy systems with five subtypes of heat-free treatment die-cast aluminum alloys, aimed at meeting performance demands across various scenarios, thus opening up new possibilities for the future of automotive manufacturing.

The tireless efforts and innovative practices of Shanghai Jiao Tong University’s research team vividly demonstrate the critical role of higher education institutions in driving industrial transformation and upgrading. For many years, Academician Wenjiang Ding and Professor Liming Peng's team has been deeply engaged in the development of aluminum and magnesium alloy materials, covering various aspects including material development, product design, process innovation, and surface treatment, thereby establishing a comprehensive industry chain technology system. Their scientific achievements not only provide solid material support for CHANGAN Automobile’s new ecosystem but also inject strong momentum into the high-quality development of China’s automotive industry.

In the future, as the NEV market continues to expand and technological advancements persist, Shanghai Jiao Tong University and CHANGAN Automobile will deepen their cooperation, exploring the integration and innovation of materials science and automotive engineering to contribute to the realization of a sustainable and green mobility future.