Researchers at Shanghai Jiao Tong University have developed a novel multi-objective high-throughput targeted method to design a NbVTaSi refractory eutectic medium entropy alloy (REMEA). This alloy possesses outstanding comprehensive properties, i.e., lightweight (7.4 g/cm3), high yield strengths at room temperature (2.60 GPa) and 850 ℃ (1.84 GPa), and excellent Ar/He-ion irradiation resistance. The study, titled“High-throughput design of a light and strong refractory eutectic medium entropy alloy with outstanding He-ion irradiation resistance”(https://www.science.org/doi/10.1126/sciadv.adq6828), was published in Science Advances with Shanghai Jiao Tong University as the lead institution.

Structural materials for nuclear systems and aerospace applications are exposed to radiation of energetic particles during their whole service life. These energetic particles can interact with lattice atoms of the structural materials and create a large number of radiation-induced defects, leading to microstructural variations that degrade material properties and accelerate material failure. With the rapid development of space propulsion, advanced fission and fusion nuclear systems, high requirements have been put forward for the lightweight, strong, and radiation-resistant comprehensive properties of structural materials. However, the existing structural materials are far from being satisfactory in harsh operating environments, making it urgent to develop a new generation of structural materials. Nevertheless, the development of new materials through experimental trial-and-error methods is time-consuming, labor-intensive, and costly, especially difficult to achieve multiple objectives simultaneously. Therefore, exploring new methods for low-cost, efficient, and precise multi-objective material design is of great significance.

High-throughput targeted design strategy flowchart of the Nb55V25Ta5Si15 REMEA

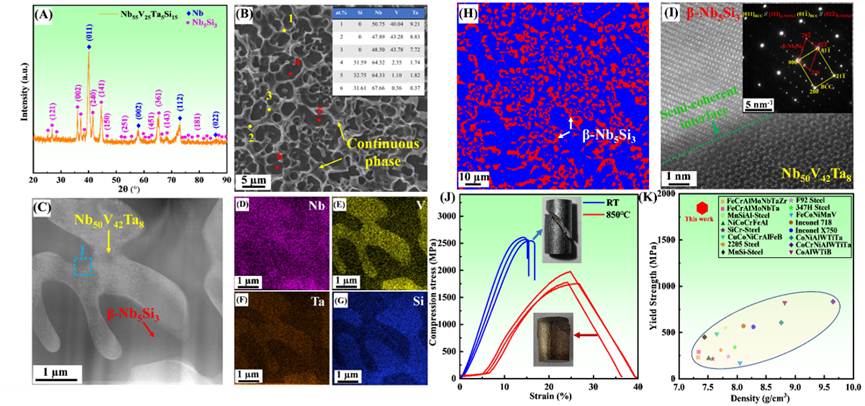

Taking into account factors such as density, melting point, phase composition, phase structure, phase content, phase size and distribution, etc., researchers designed the Nb55V25Ta5Si15 REMEA via multiple rounds of screening.

Microstructure morphology and room-/high-temperature mechanical properties of the Nb55V25Ta5Si15 REMEA

In order to verify the accuracy of the high-throughput targeted design method, researchers conducted various microstructure characterization and mechanical tests on the Nb55V25Ta5Si15 REMEA. It was found that the alloy is composed of eutectic structures and exhibits excellent room-/high-temperature mechanical properties.

He-ion irradiation behavior of the Nb55V25Ta5Si15 REMEA

Researchers conducted a study on the irradiation resistance of the Nb55V25Ta5Si15 REMEA to further verify the effectiveness of this design method. The findings revealed that the alloy exhibits excellent He-/Ar-ion irradiation resistance.

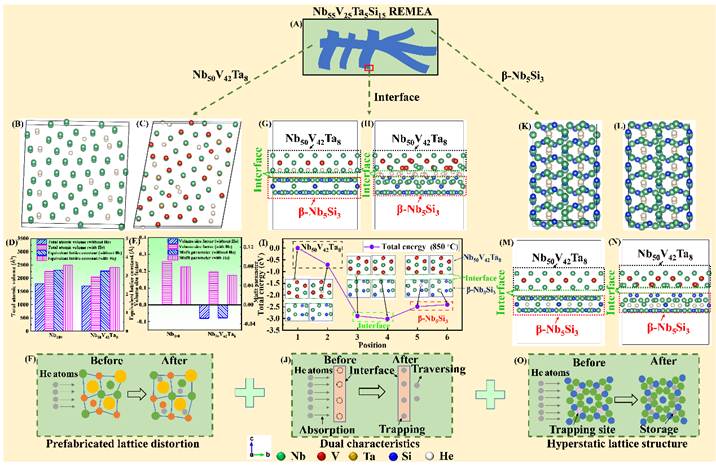

Schematic diagram of the He-induced-defect inhibition mechanism in Nb55V25Ta5Si15 REMEA

According to the first-principles calculations, researchers reveal the He-induced-defect inhibition mechanism in the Nb55V25Ta5Si15 REMEA. This novel alloy provides a potential prototype alloy for use in the first wall of the nuclear fusion devices, the cores of advanced fission nuclear reactors, or the high-temperature components of space propulsion systems. This REMEA and the high-throughput target design strategy for comprehensive properties may shed light on the development and optimization of future radiation-tolerant materials. The reviewers highly praised this design method, stating that "This work employs a wide tool set to characterize the material property comprehensively. The workflow of this study that designed and down-selected alloys from an almost infinite material space to fit the targeted application will be of interest and useful to many readers."

Assistant Professor Chao Yang from the School of Materials Science and Engineering, Shanghai Jiao Tong University, is the first author of the paper. Professor Da Shu from the School of Materials Science and Engineering, Shanghai Jiao Tong University, and Professor Peter K. Liaw from the University of Tennessee, Knoxville, are the co-corresponding authors. Other authors include Dr. Tao Wei from the Australian Nuclear Science and Technology Organisation, and Dr. Shubin Wang from the School of Materials Science and Engineering, Shanghai Jiao Tong University. The research was supported by the National Natural Science Foundation of China and the Inner Mongolia-SJTU Science and Technology Cooperation Special Project.