Inorganic semiconductors have excellent physical properties and serve as the core of modern electronics. However, inorganic semiconductors are usually brittle, so they are mostly processed by complicated techniques of sputtering or deposition, which are of high cost and time consumption. Notwithstanding the recently discovered room-temperature ductile semiconductors, the realization of decent plasticity and processibility in a vast number of brittle counterparts is urgently expected.

Recently, scientists from Shanghai Jiao Tong University (SJTU) and Shanghai Institute of Ceramics Chinese Academy of Sciences (SICCAS) have largely tackled this issue by enabling plastic warm metalworking in a series of otherwise brittle semiconductors. They developed a model for the temperature-dependent plasticity and fabricated high-performance thermoelectric devices based on the warm-metalworked semiconductor films. The research, titled "Warm Metalworking for Plastic Manufacturing in Brittle Semiconductors", was published in Nature Materials. (https://www.nature.com/articles/s41563-025-02223-9)

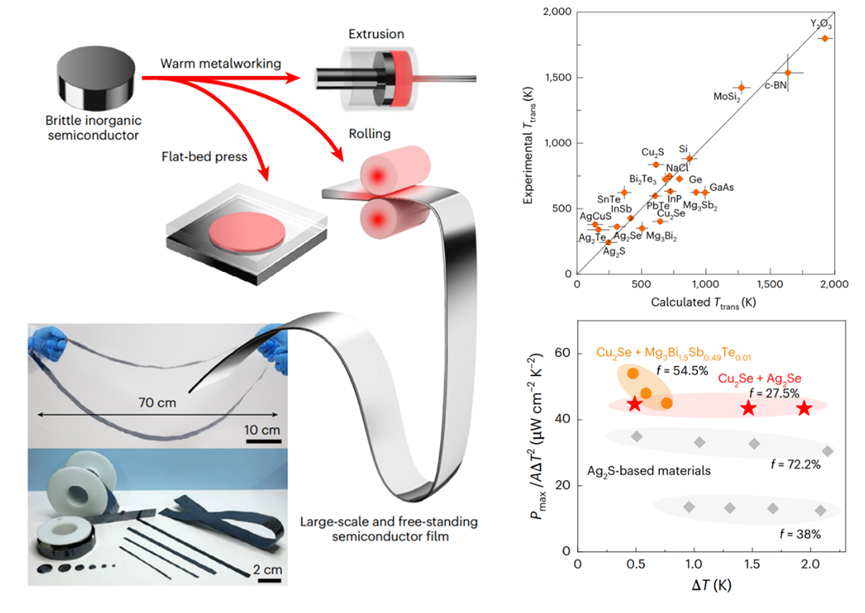

Despite the common sense that higher temperature yields better plasticity, the brittle-to-ductile transition temperature of most semiconductors and ceramics is too high (>500-700℃) for practical hot metalworking. In this study, the scientists found that a group of room-temperature brittle inorganic semiconductors (e.g. Cu2Se, Ag2Se, Bi90Sb10) exhibit excellent plasticity below ~200 °C and thus can be easily processed by various warm metalworking techniques, such as rolling, compression, and extrusion. Typically, the warm-rolled Ag2Se semiconductor strips can be as long as 90 cm, corresponding to a remarkable extensibility of ~3000%.

The warm-metalworked films have distinguished advantages, such as no substrates, freely tuned thickness from micrometers to millimeters, high crystallinity and homogeneity, and the excellent physical properties resembling the bulks. For example, the carrier mobilities of rolled Ag2Te, AgCuSe, and Ag2Se films with the thickness around 10-20 μm are as high as ~1000-5000 cm2 V-1 s-1, which is 4 times that of Si crystal and 1-3 orders of magnitude higher than that of most 2D materials and organic materials.

The researchers further revealed the rich microstructures in these warm rolled or compressed materials. Dense dislocations were not widely observed in these warm-deformed samples. Moreover, they developed a concise model based on the temperature-dependent collective atomic displacement and thermal vibration to explain the temperature-induced superior plasticity. By quantifying the temperature-dependent slip barrier energy and the cleavage energy, the model well captured the brittle-to-ductile transition temperatures for a series of inorganic semiconductors.

These meter-scale, high-quality, free-standing inorganic semiconductor films prepared by warm-metalworking methods have many potential applications in diversified electronic and energy devices. Taking thermoelectrics as a case study, the team fabricated two kinds of film thermoelectric devices based on the warm-metalworked films, yielding ultra-high normalized output power densities of 43-54 μW cm−2 K−2, almost twice that of room-temperature ductile Ag2S-based semiconductors.

This work endows various brittle semiconductors and thermoelectric materials with warm processibility, opening vast possibilities for diversified, efficient, and low-cost manufacturing.

Prof. Tian-Ran Wei from SJTU, Profs. Xun Shi and Lidong Chen from SICCAS are the corresponding authors. Dr. Zhiqiang Gao, Shiqi Yang, and Yupeng Ma are the co-first authors. Prof. Xiaoqin Zeng provided important guidance to this work. This work was supported by the National Key Research and Development Program of China and the National Natural Science Foundation of China.

Warm metalworking for plastic manufacturing in brittle semiconductors

Left: Illustration and photos of warm metalworking techniques

Right-top: Experimental vs. predicted brittle-to-ductile transition temperatures

Right-bottom: Normalized power density of thermoelectric devices based on warm-metalworked films