Recently, Prof. Li Jin and Prof. Jie Dong from the School of Materials Science and Engineering of Shanghai Jiao Tong University have made important progress in the research of mesoscopic deformation behavior of magnesium alloys. The research article, “Mesoscopic origin of damage nucleation of Mg-RE-Zn alloys containing LPSO phase” was published in the internationally renowned academic journal International Journal of Plasticity (Publication link: https://doi.org/10.1016/j.ijplas.2025.104367).

Prof. Li Jin is the corresponding author of the article. Qiankun Li, a PhD student at Shanghai Jiao Tong University, is the first author. The research work was supported by the National Natural Science Foundation of China (U2241231) and the National Key Research and Development Plan (2021YFB3701100), of which the interim assessment of the National Natural Science Foundation of China is excellent.

The research team has long been committed to the study of magnesium alloy toughening and damage mechanism, focusing on the orientation dependence of intergranular deformation in mesoscopic-scale HCP-structured magnesium alloys. For the first time, using in-situ three-point bending in combination with the EBSD method, the team has revealed that the twinning deformation of magnesium alloys interacts with dislocations (International Journal of Plasticity, 2015, 72, 218-232), and found that the twin deformation and applied macroscopic stresses do not conform to the Schmid factor principle. The team continued to develop in-situ tension and digital image technique (DIC) to quantify the relationship between local strains and grain-to-grain orientation, and the mk factor, proposed based on the geometric compatibility factor m', which can more accurately evaluate the ability of magnesium alloy to coordinate the intergranular deformation and the overall plasticity of the material (International Journal of Plasticity, 2019, 123, 121-132). The results of the previous research mainly focus on the single-phase structure of the magnesium alloy series. The research team recently studied the mesoscopic origin of damage nucleation of multiphase Mg-RE-Zn alloy containing LPSO structure and explored the interface-related damage nucleation mechanism, which has enriched the deformation and damage mechanism of magnesium alloys with multiphase configuration, and provided the theoretical basis for the design of high-strength and toughness magnesium alloys.

The research team selected Mg-RE-Zn alloys with different phase configurations as research objects and used in-situ tensile experiments combined with SEM-DIC (scanning electron microscope-digital image correlation) technology to systematically monitor and characterize the strain distribution characteristics of the alloys under different deformation and the damage nucleation process in real-time, to investigate the influence of the microstructure characteristics on the damage nucleation mechanism.

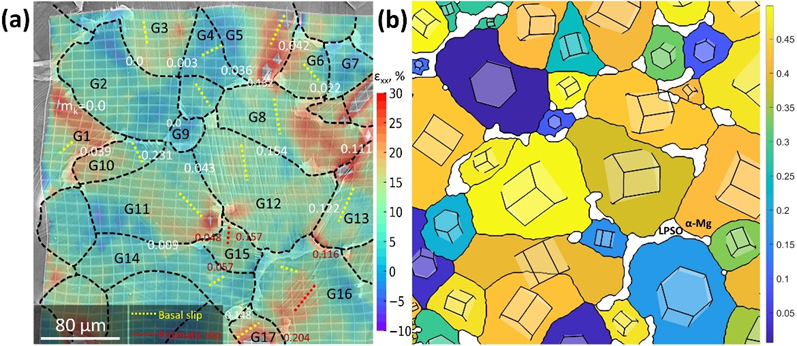

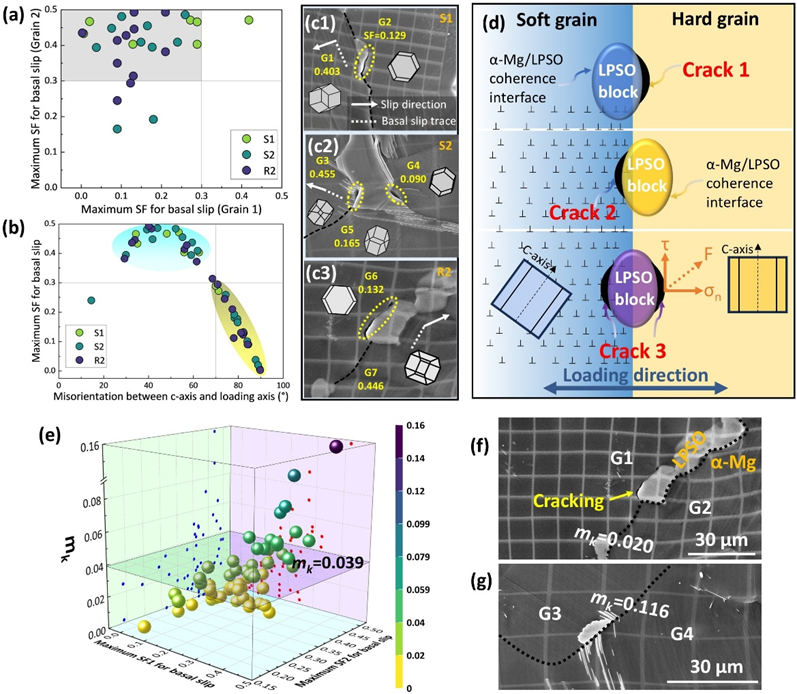

Interfaces are found to be the main location for damage nucleation, with the incoherent α-Mg/LPSO phase interface having the most significant damage propensity. Before damage occurs, strain localization occurs first near the interface, which is mainly controlled by the mk factor proposed in a previous study (International Journal of Plasticity, 2019, 123, 121-132). Strain localization generates a significant strain gradient at the interface and inside the grains, which in turn induces high local stresses and damage nucleation is triggered when the stresses exceed the interface strength. In addition, the damage behavior of the α-Mg/LPSO interface can be predicted by microstructural features: when the mk value of adjacent grain pairs is less than 0.039 and the two grains show soft and hard orientations, respectively, the incoherent α-Mg/LPSO interface between them has a high tendency of cracking. Another type of susceptible interface is the LPSO/LPSO phase interface, the damage of which mainly originates from the internal high-stress effect. Due to the high elastic modulus and hardness of the LPSO phase, the internal stress sustained during plastic deformation is significantly higher than that of the surrounding magnesium matrix, which ultimately leads to interface cracking.

According to the damage nucleation mechanism can correspond to the directional regulation of microstructure regulation. Optimization of the magnesium grain orientation increases the intergranular mk value decreases the size of the LPSO phase and increases the degree of its diffuse distribution can comprehensively enhance the strength-toughness of Mg-RE-Zn alloys.

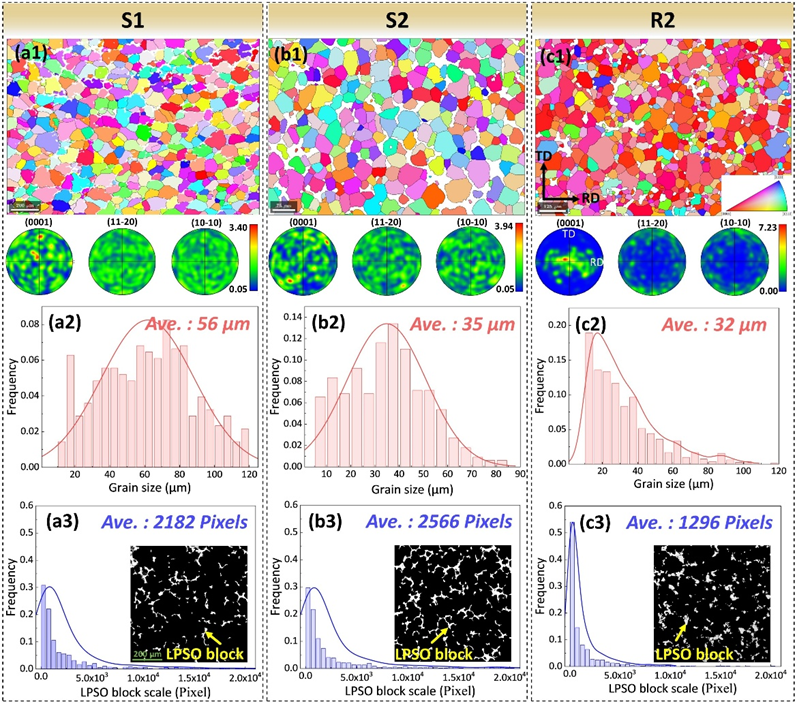

Fig. 1. Microstructure characteristics of the initial solid solution alloys. (a1, b1, c1) PF and IPF maps show the microstructure of the (a1) S1, (b1) S2, and (c1) R2 alloys, respectively. (a2, b2, c2) Histogram of the α-Mg apparent grain size expressed by equivalent circle diameter measured by EBSD data, for (a2) S1, (b2) S2, and (c2) R2, respectively. (a3, b3, c3) Histogram of the LPSO block size, expressed by SEM images pixel counts, for (a3) S1, (b3) S2, and (c3) R2, respectively. LPSO block characteristics are also expressed by binarization images illustrated in the (a3, b3, c3).

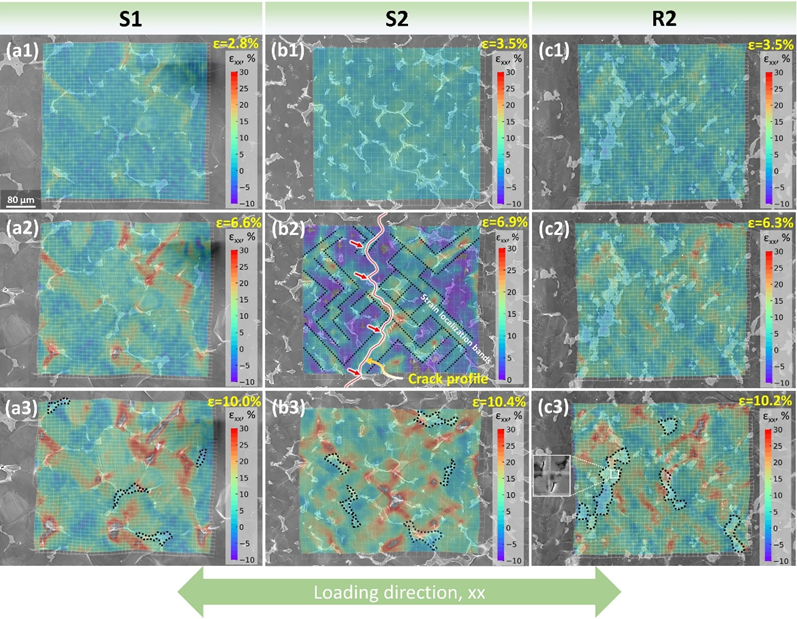

Fig. 2. Microstructure-based in-plane strain (εxx) distribution maps at different meso-strain levels for (a1, a2, a3) S1, (b1, b2, b3) S2, and (c1, c2, c3) R2. Reconstructed crack profiles extracted along the fracture surface of the S2 alloy (b2), with the corresponding strain localization bands marked by black dashed lines.

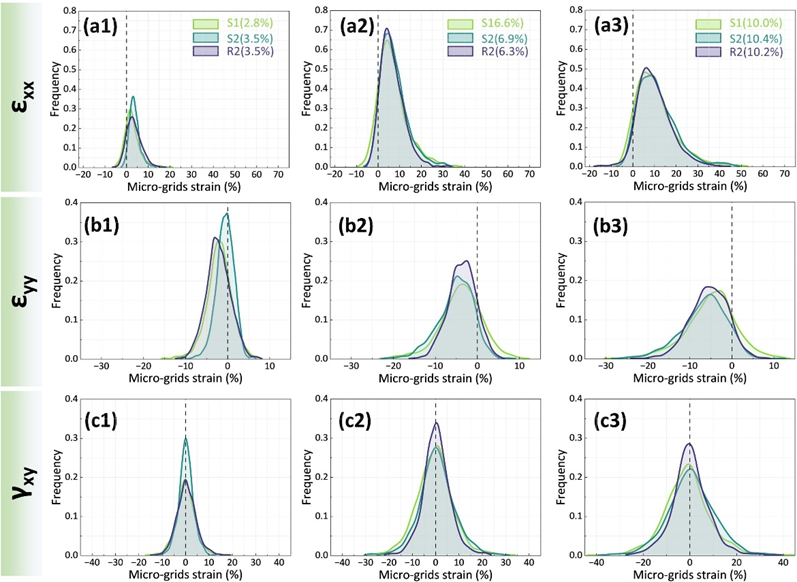

Fig. 3. Micro-grids strain distribution frequency at different meso-strain levels for (a1, a2, a3) εxx, (b1, b2, b3) εyy, (c1, c2, c3) γxy.

Fig. 4. Microstructure-based in-plane strain map of S1 alloy at a tensile strain of 10.0% (a) and corresponding maximum Schmid factor (basal slip) map superimposed on the three-dimensional orientation of the grains (b). Slip trace of the activated slip system (basal or prismatic system) and the mk value of the neighboring grains are also presented in (a).

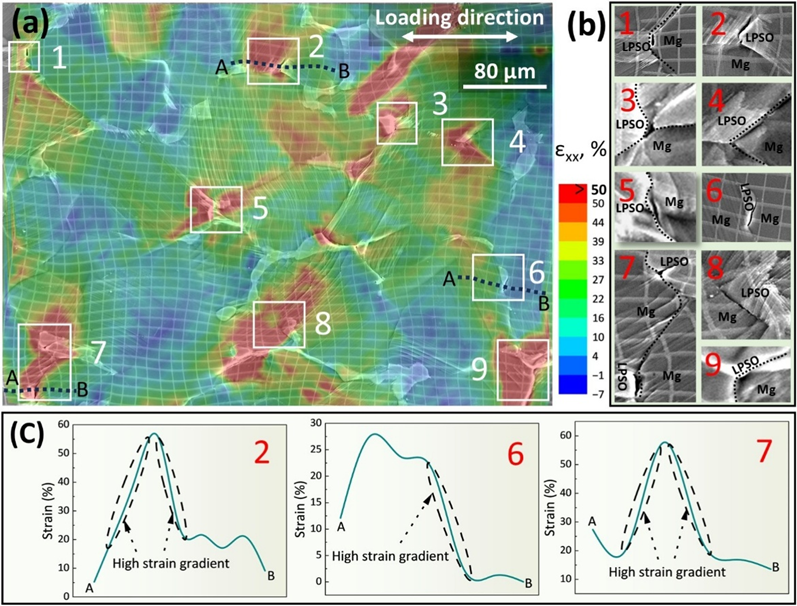

Fig. 5. Microstructure-based in-plane strain map of S1 alloy at maximum loading (a), and (b) enlarged views of the damages in (a). (c) Strain variation across several deformation bands. The white rectangles represent the α-Mg/LPSO decohesion.

Fig. 6. (a) Distribution of the maximum SF values (basal slip) of α-Mg grains on either side of the α-Mg/LPSO block crack. (b) Maximum SF (basal slip) of α-Mg grains on either side of the α-Mg/LPSO block crack plotted against the misorientation between the c-axis and the loading axis. (c1-c3) α-Mg/LPSO block cracks from (c1) S1, (c2) S2, and (c3) R2 alloys, including the three-dimensional orientation of the grains, the maximum Schmid factor for basal slip, slip traces, and projections of slip directions. (d) Schematic illustration depicting the relationship between soft-oriented and hard-oriented grains. (e) Distribution of the mk values (for basal slip) between α-Mg grains on either side of the α-Mg/LPSO block crack. (f) and (g) Microstructures of R2 and S2 alloys at a strain of ∼10%, respectively.