Xie et al.’s “Synergetic “amine scissors” break down cured epoxy resins with nearly 100% degradation efficiency” recently appeared in Chemical Engineering Journal. The research work focuses on exploring “cutting” methods with high efficiency and high selectivity for the degradation of waste cured epoxy resins. This work is done by a joint team and the team is led by Guo-Ming Weng, associate professor of Shanghai Key Laboratory of Hydrogen Science & Center of Hydrogen Science, School of Materials Science and Engineering at Shanghai Jiao Tong University. Other contributors are from Agilent Technologies (China) and Jilin University. The abstract appears below.

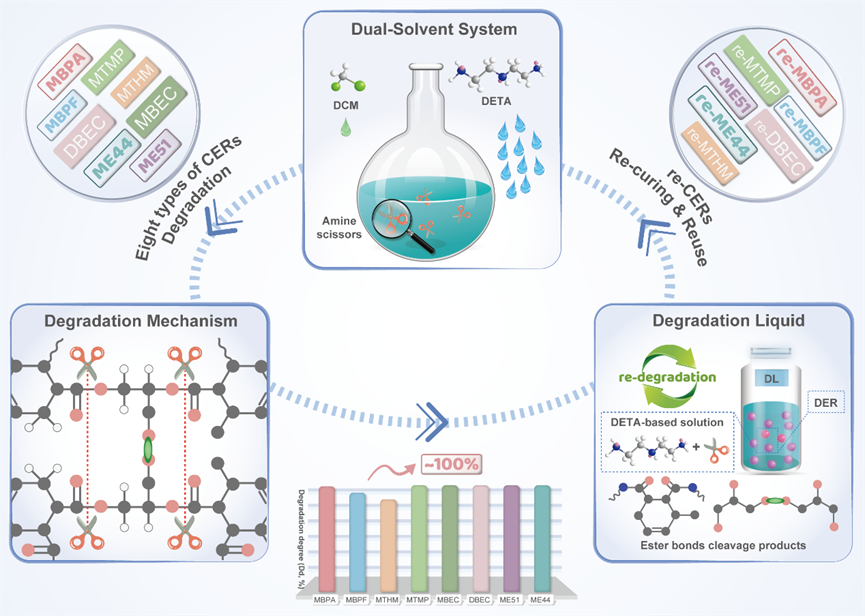

“Thermoset polymers are widely established in regard to high-tech fields and industrial sectors, owing to their high strength, good heat resistance and excellent electrical properties. The recycling of waste cured epoxy resins has been challenging due to their rigid three-dimensional network structure. Therefore, it is critical to explore “cutting” methods with high efficiency and high selectivity for their degradation. Herein, we show sharp “amine scissors” (originated from the reaction of diethylenetriamine and dichloromethane) with ultrahigh degradation degree of ∼ 100 % and fast degradation rate of 119.99 % h−1 for up to eight types of cured epoxy resins (including two commercial products) under mild conditions. It is worth noting that i) this concept can be further generalized to other solvent combinations; ii) pre-immersion/expansion step could be also skipped; and iii) the degradation rates of the bulk cured epoxy resins without fine pulverization by the method described herein are still up to 100 %, holding great promise to recover glass fibers from epoxy resin-based composite materials containing ester bonds. These remarkable results are enabled by a synergistic effect from the as-generated amines with different nucleophilic ability and alkalinity in the ester bond amination or breakdown process, which is supported by experimental and theoretical investigations. Moreover, the resultant constituent molecular parts are then recovered and reused to yield new cured epoxy resins with high performance. Therefore, this unique strategy could enable ultrahigh-efficiency recycling of most cured epoxy resins and their composites towards a more “circular” epoxy resin industry. In line with other exciting achievements highlighted in the literature, this work provides a sort of striking conceptual advance to promote circular economy of epoxy resins and their composites.”

Figure 1. The graphical abstract of the striking conceptual advance reported in this work.

This work is supported by National Key R&D Program of China (2022YFC3900700), Shanghai Key Laboratory of Hydrogen Science & Center of Hydrogen Science of Shanghai Jiao Tong University, and Shanghai High-Level Oversea Talents Award, etc.

Read the full article: https://doi.org/10.1016/j.cej.2025.161175