Metamaterials are a class of artificially engineered materials with extraordinary properties not found in nature. These materials exhibit unique characteristics and have wide-ranging applications in fields such as imaging, communications, energy, and aerospace. Among them, thermal radiative metamaterials can “package” and emit excess heat to the space. Wearing “clothing” made from such materials is like putting on a “cooling magic garment”, enabling automatic temperature regulation for objects. These materials hold significant promise for applications in zero-energy-consumption radiative cooling, thermal management of electronic devices, and personal thermal comfort applications.

How can we design thermal radiative metamaterials that precisely meet performance requirements both quickly and effectively? This has long been a challenge for scientists. However, traditional design methods are time-consuming and labor-intensive: the microstructure—the key to metamaterials’ ability to surpass natural material limitations and achieve extraordinary properties—involves millions of possible parameter combinations. It’s like groping through a maze in the dark, often relying on extensive experience and trial-and-error.

But everything changed with the introduction of artificial intelligence (AI) into thermal radiative metamaterial design. On the evening of July 2 (Beijing time), a research team led by Shanghai Jiao Tong University published a groundbreaking study in Nature, marking a major original breakthrough in the field of AI-driven thermal meta-emitters. Instead of tweaking existing “recipes”, the team developed an AI-powered inverse design model that breaks through the “performance ceilings” of current designs. This model can rapidly mass-generate high-quality candidate structure for thermal radiative metamaterials and identify the most engineering promising ones.

Figure 1. Title page screenshot of the article published in Nature

Developing an Inverse Design AI Model for High-Throughput thermal Metamaterial Design

Thermal emission, a fundamental feature of nature, acts like an tireless “courier of heat”, it constantly carries thermal energy away from all objects. For example, when we bask in sunlight and feel its warmth, our skin is essentially receiving solar thermal radiation. Over billions of years of natural selection, many organisms have evolved sophisticated three-dimensional (3D) topological structures with extraordinary optical and thermal properties. These structures enable them to regulate their body temperature via thermal radiation management.

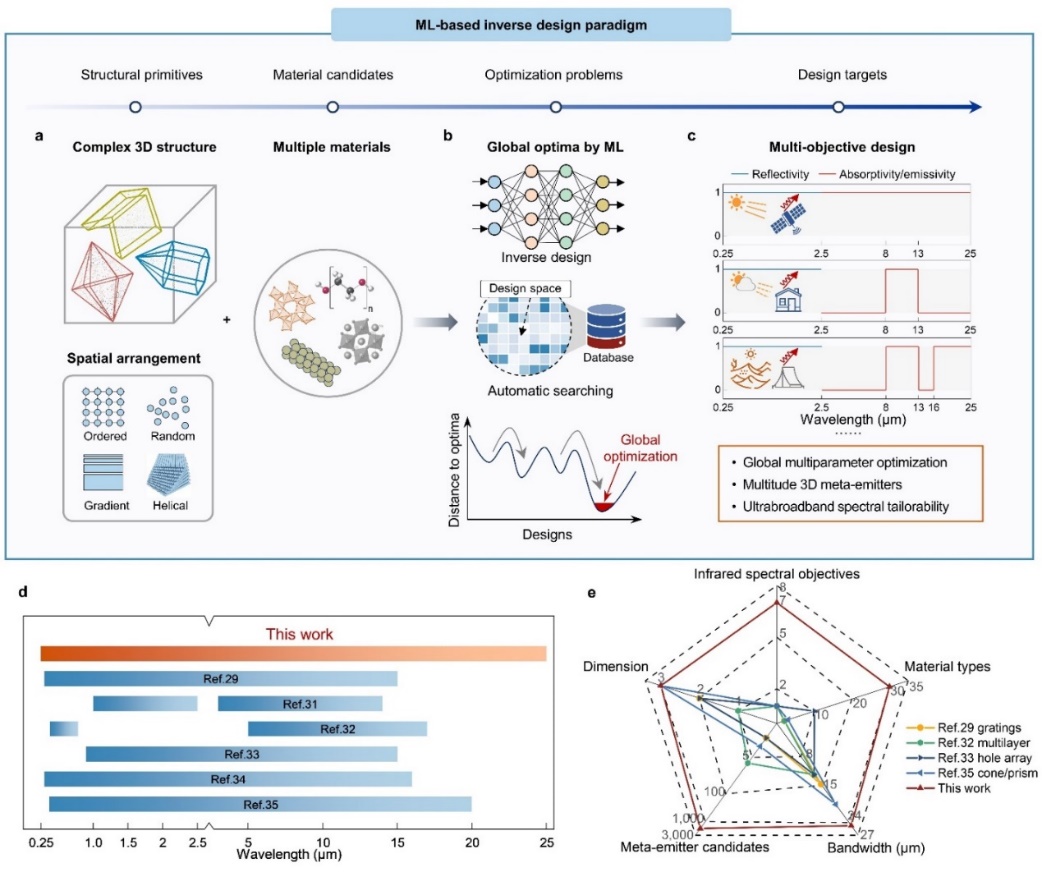

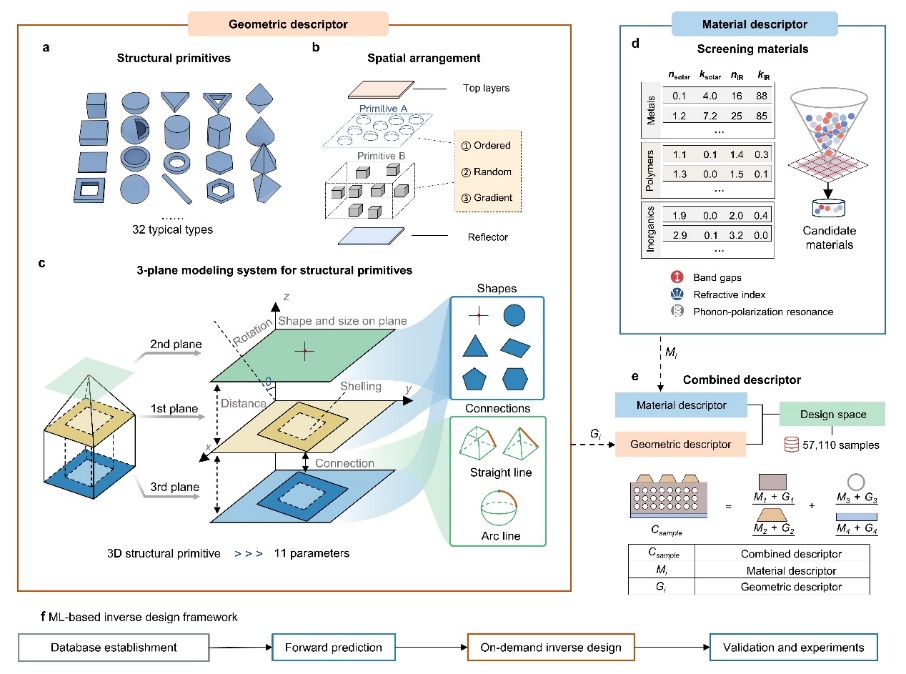

Inspired by the 3D topological structures found in nature, the research team extracted a variety of 3D structural units and spatial arrangements. They developed an innovative “three-plane modeling” method, which enables precise geometric descriptions of these complex structures and laid the foundation for a large-scale dataset of intricate 3D architectures. By integrating this structural library with diverse material systems, the team trained an AI model capable of rapidly and accurately generating multiple design solutions for thermal radiative metamaterials based on desired spectral properties. This approach marks a comprehensive leap forward in terms of design dimensionality, speed, and performance. The engineered thermal radiative metamaterials hold great promise for applications, including zero-energy-consumption radiative cooling, energy-efficient building temperature regulation, aerospace thermal management. This innovation significantly accelerates both scientific progress and industrial deployment in related fields.

The research was led by Professor Han Zhou’s group from the State Key Laboratory of Metal Matrix Composites, School of Materials Science and Engineering; Zhangjiang Institute for Advanced Study, Shanghai Jiao Tong University. It was a joint collaboration with the teams of Academician Di Zhang (Director of the State Key Laboratory of Metal Matrix Composites), Professor Cheng-Wei Qiu from the National University of Singapore, and Professor Yuebing Zheng from The University of Texas at Austin. The team’s breakthrough findings were published in Nature under the title: “Ultrabroadband and band-selective thermal meta-emitters by machine learning”. Professor Han Zhou, Academician Di Zhang, Professor Cheng-Wei Qiu, and Professor Yuebing Zheng are co-corresponding authors of the paper. Chengyu Xiao, a PhD student at the School of Materials Science and Engineering, Shanghai Jiao Tong University, is the first author. Shanghai Jiao Tong University is the first affiliated institution. This work was supported by the National Natural Science Foundation of China, the Shanghai Science and Technology Development Fund, and the SJTU 2030 Initiative. The project has been granted software copyright and related invention patents have been filed.

Figure 2. Paradigm and key characteristics of AI-driven inverse design for thermal metamaterials

Figure 3. Parametric description method and inverse design workflow

Experimental validation with multiple material types meets diverse application needs

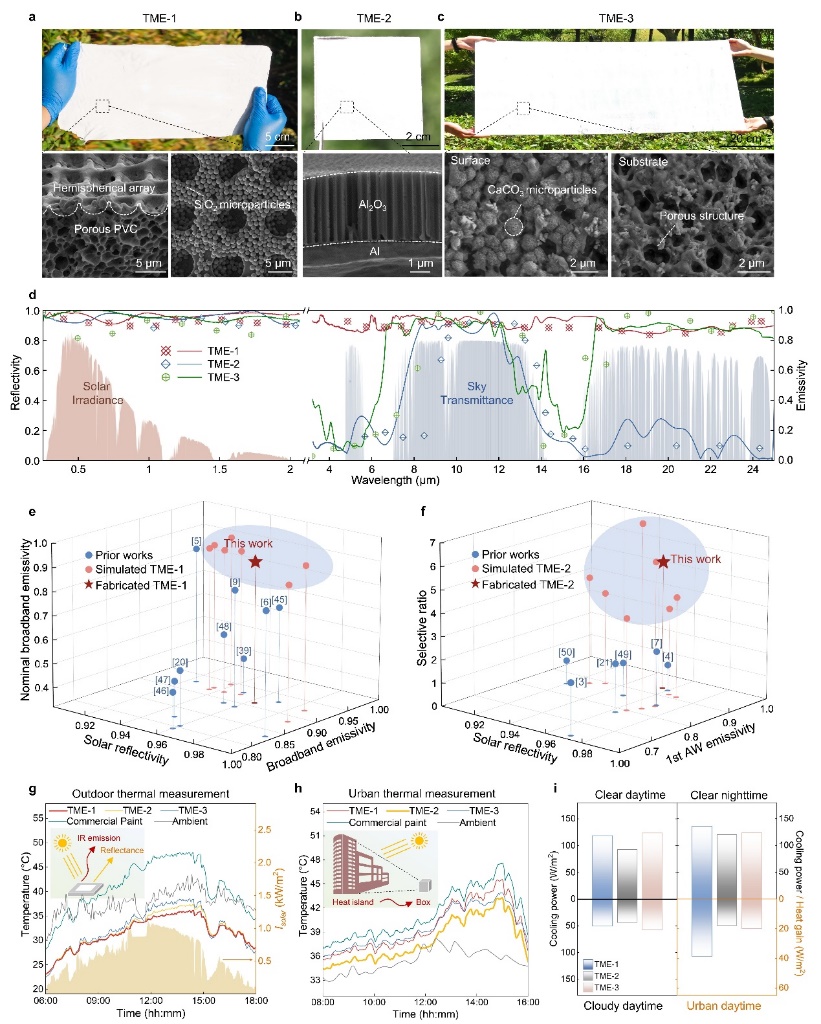

To validate the practical effectiveness of the AI model, the team designed and experimentally verified seven types of thermal radiative metamaterials tailored for specific applications. These included broadband, band-selective, and dual-band selective thermal radiative metamaterials. The actual implementations spanned various formats such as flexible films, coatings, and patches.

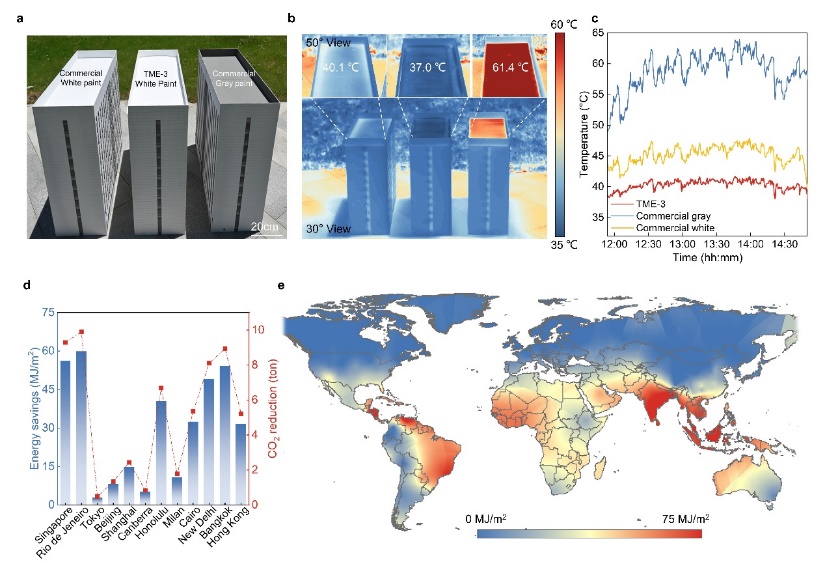

In various outdoor field tests, the thermal radiative metamaterials designed by the AI model consistently demonstrated excellent passive cooling performance. Different types of materials proved suitable for diverse application environments, effectively acting like “automatic cooling coats” tailored to the specific conditions. For example, under clear midday, the surface temperature beneath the broadband metamaterial was 5.9 °C lower than the ambient temperature. Under cloudy conditions, the band-selective metamaterial showed even more pronounced cooling, with a surface temperature 4.6 °C below ambient. In a simulated urban building environment, the surface temperature under the band-selective metamaterial was 2.5 °C and 5.3 °C lower than those under the broadband metamaterial and commercial white paint, respectively. Wearing this “automatic cooling coat”, the surface temperature drops significantly, effectively activating a natural cooling mode.

When coated on a model rooftop, the dual-band selective metamaterial reduced the surface temperature by 5.6 °C compared to commercial white paint and by 21 °C compared to gray paint, instantly cooling down the scorching roof. These results compellingly demonstrate the AI model’s capability for “wish-based” material design, highlighting its potential applications in building energy efficiency and urban heat island mitigation. This breakthrough offers an innovative solution toward creating future zero-energy cooling cities.

Figure 4. Experimental validation and outdoor thermal testing results for typical radiative cooling demands

Figure 5. Application and energy-saving evaluation as building envelopes

Facilitating scalable material fabrication to accelerate real-world applications

This AI model not only “invents” novel materials but also selects those better suited for large-scale use and lower cost. Take the typical dual-band selective metamaterial as an example: it can be simply fabricated at room temperature via a straightforward solution process. Applied as a coating, it can be directly used on common surfaces such as brick walls, metals, plastics, and glass—like putting on a “sunscreen-cooling cream” that cools down the object. Energy consumption simulations show that when applied to building rooftops in mid- to low-latitude regions, the material can achieve a theoretical energy savings of 75 MJ/m²—equivalent to about 20 kWh of electricity. Moreover, this material is cost-effective and versatile in application—from building exteriors to wearable clothing, outdoor facilities to electronic devices. This affordable “cooling champion” is poised to make high-tech cooling accessible to households everywhere.

Figure 6. Prof. Zhou’s research team (Professor Han Zhou, middle)

Original source link: https://www.nature.com/articles/s41586-025-09102-y