Recently, the research team of Prof. Liu at the Shanghai Key Laboratory of Hydrogen Science and the Center of Hydrogen Science has made significant progress in studying the mechanism of vapor-phase dealloying. The findings were published in the internationally renowned academic journal Physical Review Letters under the title “Resolving Elementary Steps of Vapor-Phase Dealloying via In Situ Transmission Electron Microscopy.”

Associate Professor Pan Liu from Shanghai Jiao Tong University and Associate Professor Qing Chen from Hong Kong University of Science and Technology served as co-corresponding authors of the paper, with doctoral candidate Xinyao Wang from Shanghai Jiao Tong University as the first author. This research received substantial support from collaborators, including Prof. Yuqiao Zeng from Southeast University and Prof. Mingwei Chen from Southern University of Science and Technology. It was funded by the National Natural Science Foundation of China (Project Nos. 52173224, 52130105) and the Shanghai Natural Science Foundation (Project No. 23ZR1431500).

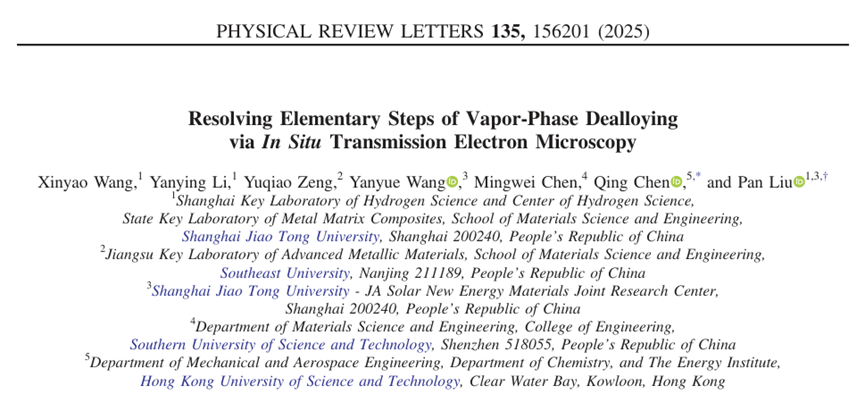

Nanoporous metals, with their high specific surface area and continuous pore structure, demonstrate broad applications such as catalysis, energy, and sensing. These materials are typically prepared via the dealloying method, wherein specific components are selectively removed from alloys, causing the remaining components to spontaneously reorganize into a three-dimensional nanoporous structure. However, direct experimental evidence supporting the mechanisms of pore formation and evolution during dealloying—particularly at the nanoscale or atomic level—has long been lacking. Existing theories are largely based on ex-situ characterization and computational simulations, necessitating validation through in situ experimental techniques with high spatiotemporal resolution to deepen our understanding of dealloying mechanisms.

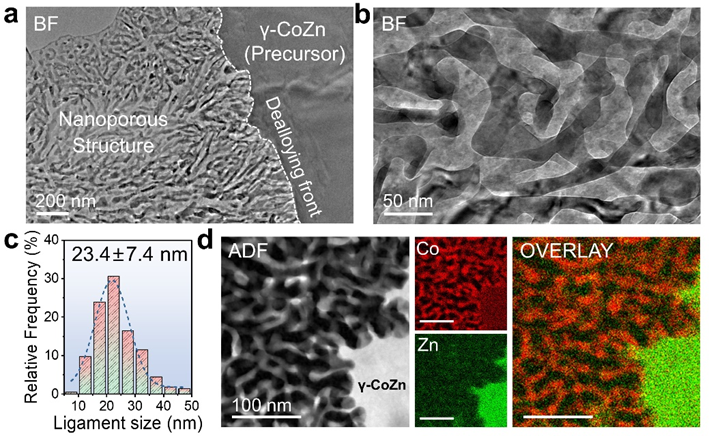

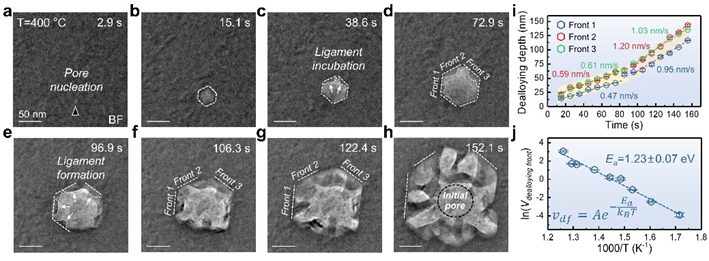

To address these challenges, the research team leveraged the inherent high-vacuum environment and in situ heating technique of transmission electron microscopy (TEM). They successfully activated the vapor phase dealloying (VPD) process of a γ-CoZn alloy precursor within the TEM chamber and performed in situ observations. The experiments comprehensively revealed the entire process from initial pore nucleation and evolution to the final formation of a three-dimensional nanoporous structure. Further investigations revealed that the dealloying front propagates layer-by-layer into the precursor. This process occurs through pit nucleation on the crystal planes, forming the dealloying fronts, and subsequent step flow. Statistical analysis of dealloying rates and step flow rates at different temperatures indicates that zinc sublimation at the dealloying front, rather than surface diffusion of residual cobalt atoms, is the rate-limiting step in VPD. The activation energy for dealloying, exceeding that of pure zinc sublimation, indicates that the strong bonding energy of Co-Zn bonds within the alloy precursor significantly influences dealloying kinetics. This finding corrects the limitation of classical dealloying theory, which solely relies on coordination number as a criterion for dissolution.

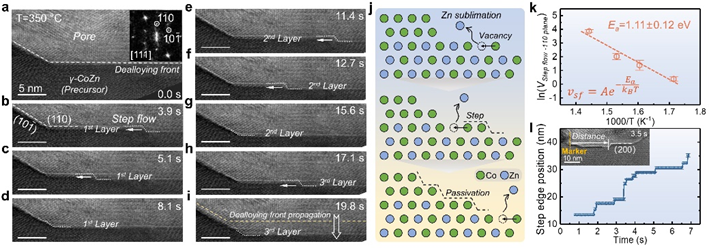

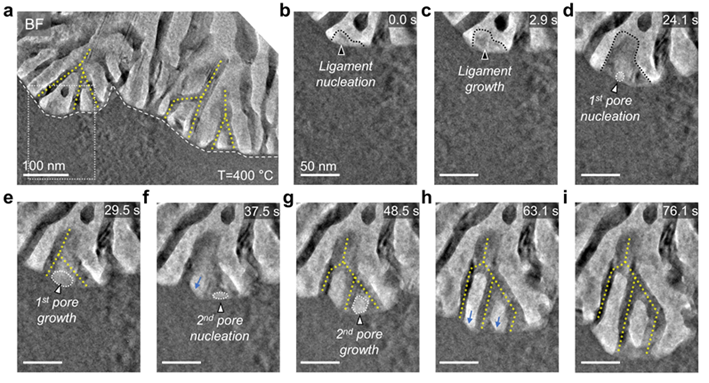

The study also observed intermittent migration of surface steps, potentially arising from the adsorption of cobalt atoms with low coordination number. Such kinetic features may potentially influence the morphology of pores and ligaments, particularly in the aspect ratio of porous structures. Furthermore, the study reveals the origin of pore and ligament bifurcation: dynamic passivation by residual cobalt atoms promotes pore bifurcation, while its failure induces ligament bifurcation. This work not only provides the first atomic-scale visualization of the entire VPD process but also establishes the pivotal role of bond energy in dealloying kinetics. These findings offer significant guidance for designing and optimizing nanoporous materials and provide new insights into understanding non-conservative phase transformation beyond dealloying, such as oxidation-reduction processes.

Figure 1. Nanoporous structure formed by vapor-phase dealloying (VPD) in the transmission electron microscope (TEM).

Figure 2. Structural evolution and kinetic analysis at the initial stage of vapor-phase dealloying.

Figure 3. Atomic-scale analysis of dealloying front propagation and kinetic analysis of step flow.

Figure 4. In situ observation of the pore and ligament bifurcation.