Recently, the research team of Prof. Gu Jianfeng and Prof. He Quanfeng from the School of Materials Science and Engineering at Shanghai Jiao Tong University, together with several international collaborators, have made important progress in understanding and engineering topologically close-packed (TCP) phases in high-performance structural alloys. Their work, titled “Polytypical Phase Transformation of Topologically Close-Packed Phase Enabled Toughening in Multi-Principal-Element Eutectic Alloy” has been published in Acta Materialia. This study reports a breakthrough in solving the long-standing brittleness problem of TCP phases, materials known for excellent high-temperature strength but notorious for their catastrophic fracture behavior at room temperature. The team demonstrates that a specially designed metastable multi-principal-element TCP phase (the M phase) can undergo a reversible, shear-activated polytypic transformation into a C14 Laves phase under stress, enabling an unprecedented combination of high strength, ductility, and toughness in a TCP-rich alloy.

TCP phases such as Laves phases are widely used in superalloys, hydrogen-storage materials, and superconductors due to their exceptional high-temperature strength and creep resistance. However, their notorious brittleness at room temperature, associated with limited slip systems, directional bonding, and weak grain boundaries, has long restricted their use in environments requiring both strength and toughness. Traditional strategies such as microalloying or introducing antisite defects have had limited success, and even when TCP phases are used merely as strengthening particles, their volume fraction must remain low to avoid catastrophic fracture. This brittleness has therefore formed a deeply entrenched strength–toughness trade-off in intermetallic-reinforced alloys.

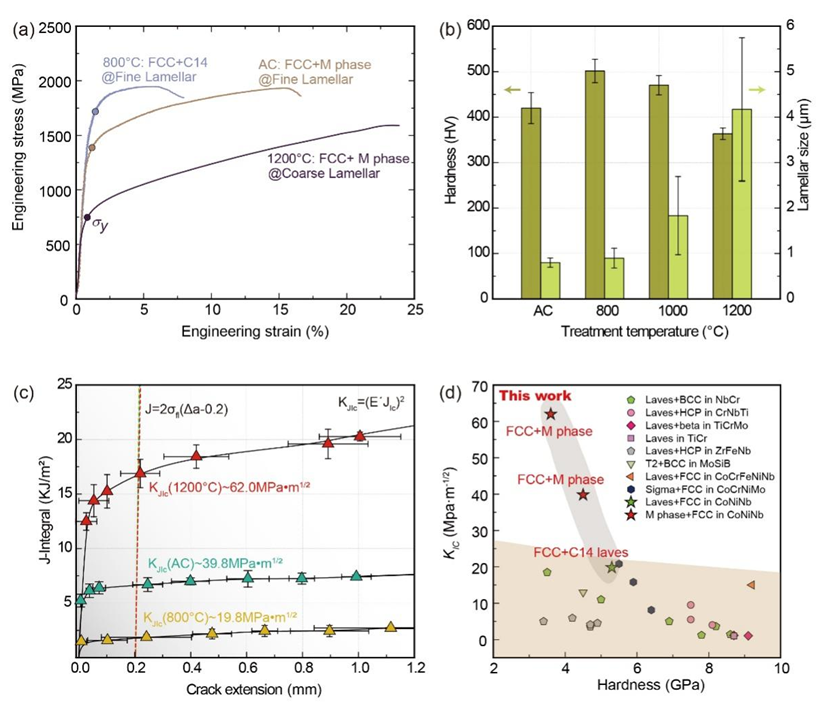

The current work challenges this paradigm by engineering a chemically complex eutectic alloy that incorporates nearly 50 vol.% TCP phases while still exhibiting exceptional mechanical resilience. The researchers discovered that the metastable M phase, present in the Co–Ni–Nb eutectic alloy, possesses a long-period stacking structure and is capable of transforming into a C14 Laves phase when subjected to mechanical stress. In-situ high-energy X-ray diffraction experiments show that C14 diffraction peaks emerge as the applied stress increases, while peaks corresponding to the M phase diminish. Upon unloading, the M phase partially recovers, demonstrating a reversible polytypic transformation behavior. Transmission electron microscopy further confirmed that this transformation proceeds through a shear-dominated rearrangement of atomic layers, enabling significant intrinsic crack-tip plasticity, an extraordinary phenomenon for alloys containing such a high fraction of TCP phases.

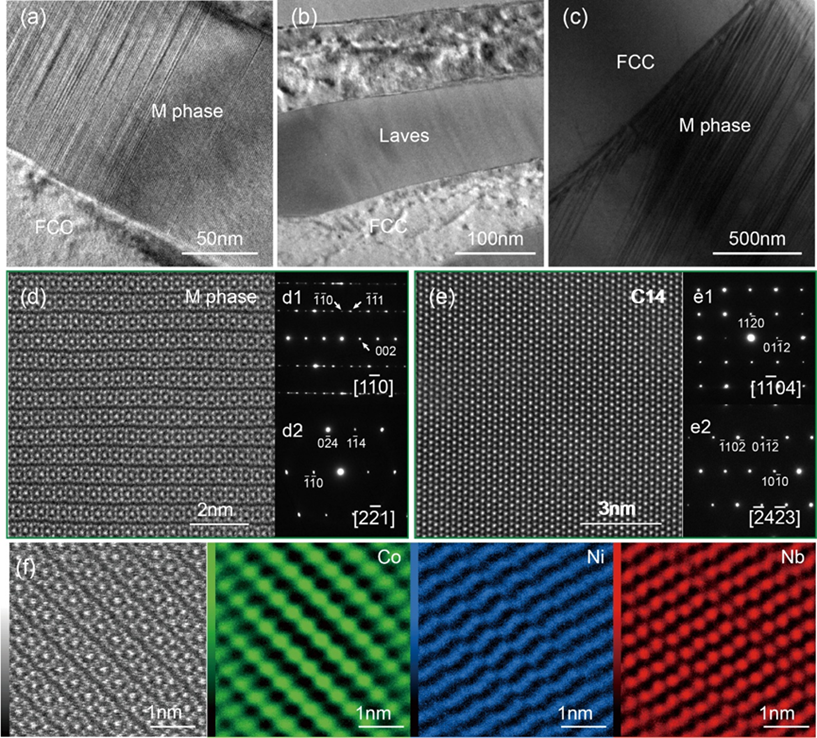

This deformation-induced polytypic transformation leads to a remarkable enhancement of fracture toughness. Using single-edge notched bend (SENB) tests following ASTM standards, the authors report that the eutectic alloy achieves an unprecedented room-temperature fracture toughness of approximately 62 MPa·m0.5, far exceeding all previously documented values for TCP-strengthened alloys, which typically fall below 10 MPa·m0.5. Extensive crack-tip blunting, tortuous crack propagation paths, and the presence of ductile-like fracture features further confirm the transformation-enabled toughness. Even more striking is the alloy’s thermomechanical resilience: through cyclic compression combined with thermal reversion at 1200 °C, the alloy successfully withstands cumulative compressive strains exceeding 75% without cracking, a level of formability previously considered unattainable for any TCP-rich material.

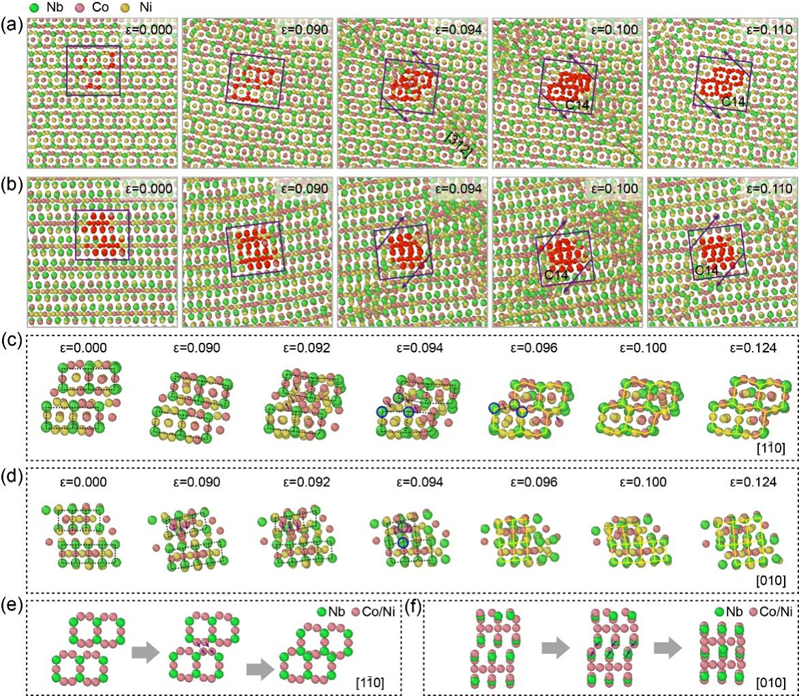

Beyond experimental observations, the research team developed a machine-learning interatomic potential trained on extensive density functional theory datasets to elucidate the atomic-scale mechanism underlying the M-to-C14 transformation. Large-scale molecular dynamics simulations reveal that the transformation proceeds through shear-driven restructuring of atomic planes while maintaining the overall Nb backbone. This mechanism distinguishes the transformation from classical martensitic behavior and highlights the critical role of metastability and polytypic transformation in enabling reversible structural rearrangements. The combination of atomistic modeling and experimental validation provides a comprehensive understanding of this unusual deformation pathway.

This study presents a new design strategy for advanced intermetallic alloys by demonstrating that metastable TCP phases can be deliberately engineered to serve not as brittle structural liabilities, but as dynamic, energy-dissipating components. The reversible polytypic transformation discovered here fundamentally redefines the mechanical potential of TCP phases, breaking the traditional strength–toughness trade-off and opening new possibilities for designing strong, ductile, and processable materials for extreme environments. The findings could have far-reaching implications in aerospace, energy systems, and any application where conventional TCP phases have been limited by their brittleness.

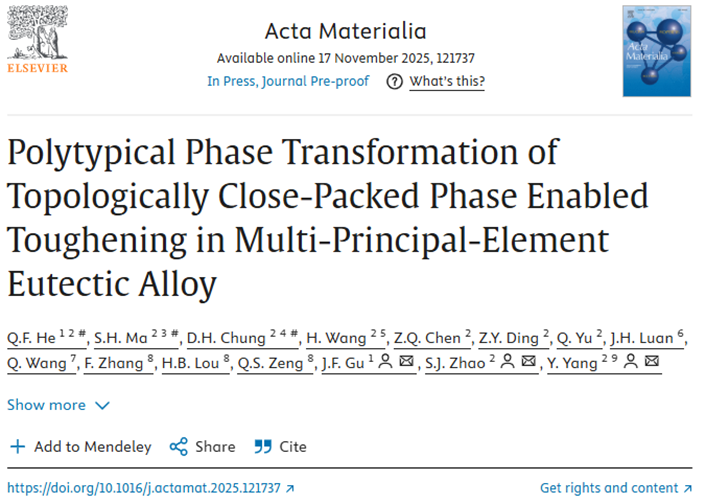

Figure 1. (a-c) The TEM images of the CoNiNb0.37 eutectic alloy at as cast, 800℃ annealed and 1200℃ annealed conditions. (d) The STEM-HADDF image and SAED patterns of the M phase in the as-cast eutectic alloy. (e) The STEM-HADDF image and SAED patterns of the C14 laves phase. (f) The elemental mapping of the M phase along the  zone axis.

zone axis.

Figure 2. (a) Engineering stress-strain curves of as-cast, 800℃ annealed, and 1200℃ annealed samples. (b) Microhardness and lamellar size of samples post-annealing at varying temperatures. (c) J-R curves derived from fracture toughness tests of the as-cast, 800℃ annealed and 1200℃ annealed samples. (d) Fracture toughness KIC plotted against the hardness of the current alloy compared to other TCP phase reinforced alloys.

Figure 3. (a) In-situ high-energy X-ray diffraction patterns captured from the as-cast CoNiNb0.37 eutectic alloys under varying stress levels. (b) Variation of d-spacing under applied stress for different lattice planes in the M phase and C14 Laves phase. (c) TEM image illustrating the eutectic alloy with a dual-phase structure of M phase and FCC prior to deformation. (d) SAED pattern corresponding to the M phase in (c). (e) Dark-field TEM images post deformation revealing the transformation of M phase to C14 Laves phase. (f) SAED pattern of C14 Laves phase in the deformed eutectic structure.

Figure 4. (a) and (b) Atomic configurations at different strain levels from compression simulations viewed along the  and [010] directions, respectively. (c) and (d) The atomic cluster evaluations in the highly deformed regions at different strain levels viewed along the

and [010] directions, respectively. (c) and (d) The atomic cluster evaluations in the highly deformed regions at different strain levels viewed along the  and [010] directions, respectively. (e) and (f) The schematic illustrations of the atomic movement during the M to C14 phase transitions viewed along the

and [010] directions, respectively. (e) and (f) The schematic illustrations of the atomic movement during the M to C14 phase transitions viewed along the  and [010] directions, respectively.

and [010] directions, respectively.